-

12-01-2013 #21

-

12-01-2013 #22

This is what I think I would need machined to take the bearing blocks at the drive side. The top pic shows whats there and the bottom shows what I think I need.

As there is not enough material, I would need to chop the current machined end off and weld a new one in to give me the material I need for the new design.

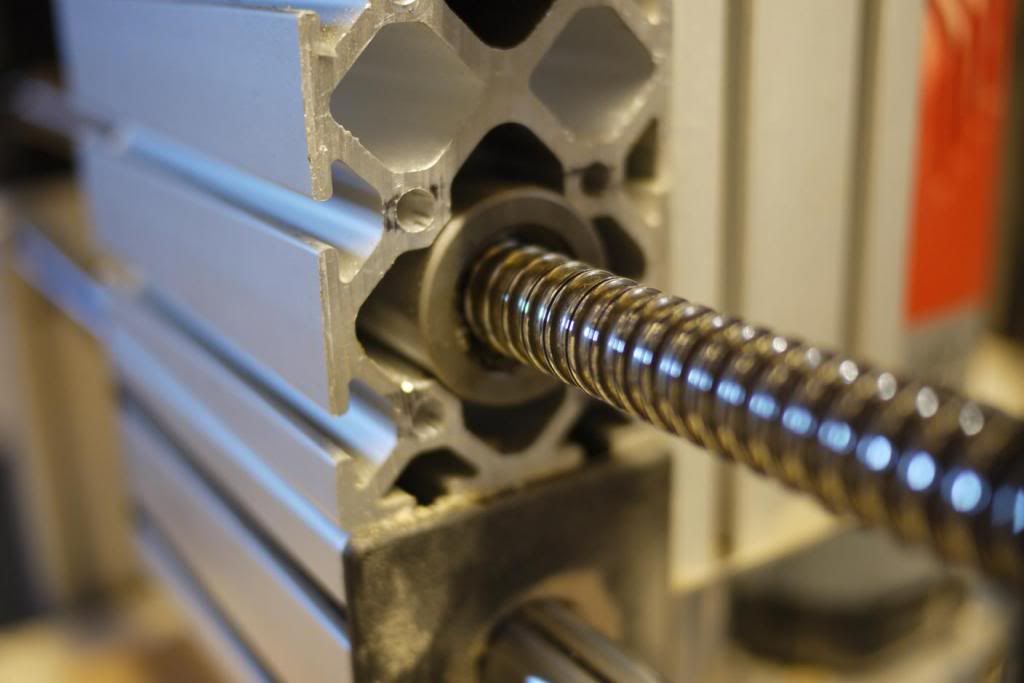

This is how I have machined my ballscrews before as my lathe aint up to the job of machining the hardend casing off. It makes the maching a lot easier anyway and as the welded on blank is oversized when it is turned down in the lathe it brings itself concentric with the screw.

Something like this for the bearing block?

http://www.zappautomation.co.uk/en/f...7-fk08-c7.html

Its a little smaller than the recommended block but I doubt it will matter too much for this router as I am only looking get something in there that will work relative to the limits of the rest of the machine.Last edited by gavztheouch; 12-01-2013 at 04:16 PM.

CNC routing and prototyping services www.cncscotland.co.uk

ADD ME ON FACEBOOKS

ADD ME ON FACEBOOKS

-

12-01-2013 #23

-

12-01-2013 #24

That looks like a Myford lathe and with the correct cutting tool will handle machining ballscrews, my little boxford does. But with this job then it wouldn't hurt to anneal the end up to remove hardening.

From the pics of motor with screw then there is a bit screw left with enough room for a nut so just thread the whole lot then grind flat spot for coupler screw, you may have to machine a new coupler or a sleeve.? . . . Sure it could be done easier than welding bits onto screw.!!

-

12-01-2013 #25

That bearing block from zapp would do nicely. You could fit one either end of the screw on the inside faces. All you would need to do is machine down the shaft to fit the bearing and they would still be long enough to fit back on.

-

13-01-2013 #26

I had one (sold it) with the trapezoid screws on it. From the way that They make their set up you should have just enough to put that FK block in on the inside and if you got an FF block as well for the other end you should be able to get rid of the play with the grub screw and a bevel washer or two (someone correct my spelling of those please). That or you could go with an angular contact bearing on the free with said washer and grub screw. Good luck on getting it to cut better, If that is the model with the unsupported round rails on Y you might want add a plate across that back to improve rigidity.

He has changed design a little bit over the last 4 years, depending on which year model depends on what needs to be done to make it work at anywhere near the capacity that they state it can. Let's just say I was not overly impressed with my machine and the work I had to do on it to get any where near accurate cutting from it, compared to what I was told it was capable of. Hence the reason for the machine I currently use.

Michael

-

13-01-2013 #27

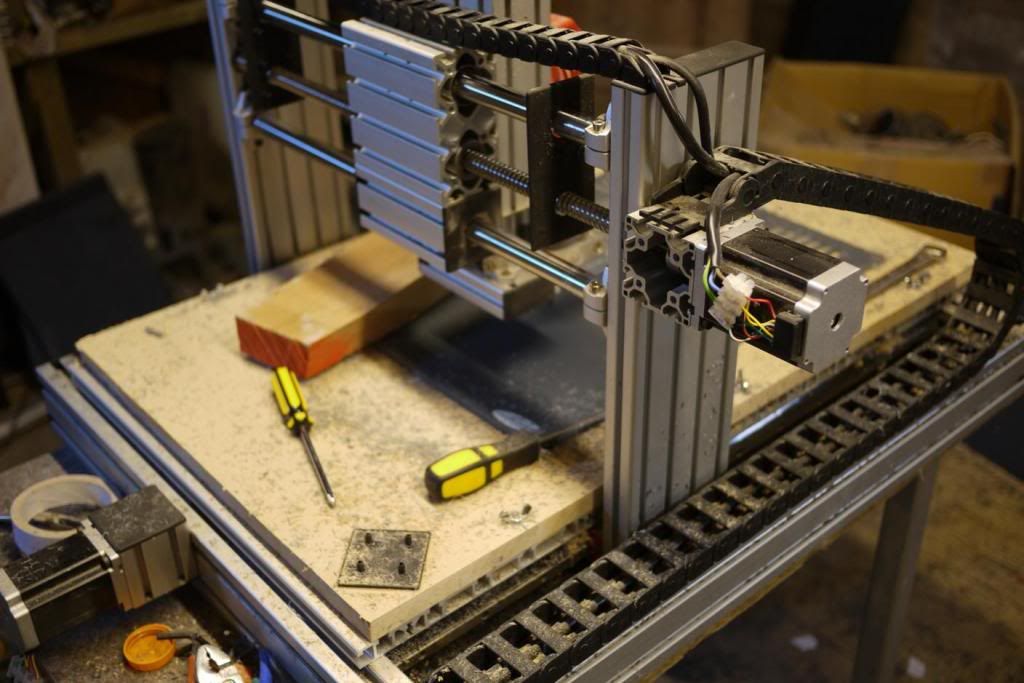

Hi Michael, my machine is around a year old. It has hiwin profile rails on the long axis and unsupported rounds on the other two. Ballscrews on all three axis.

In soft plastic and foam it is really accurate and I can get rapids of 3000mm/min pretty easily and smoothly.

Its really only with harder materials it begins to struggle, luckly I have had quite a lot of work given to me for prototyping in soft plastic which has made the machine pay its way.

I don't know if it is worth modding the machine to be able to process hardwood, I could keep it solely for softplastic and modelling foam. But if I could do it with as little risk to ruining the orginal machine as possible it may be worth the risk and effort.

I think the easiest way to achive this would be a ballscrew support/fixing block from zapp, and to mount this on the side that is not driven. This would mean buying to blocks at about £35 each plus modding the ballscrews. Total cost about £100 and two days work.

Out of interest which machine are you running now Michael?CNC routing and prototyping services www.cncscotland.co.uk

ADD ME ON FACEBOOKS

ADD ME ON FACEBOOKS

-

13-01-2013 #28

Michael doesn't use a branded machine, you can read the build log for it here.

http://www.mycncuk.com/forums/router...d-machine.html

-

15-01-2013 #29

Digging a little deeper I noticed the ballnut for the x-axis is simply pressed into the extrusion, it looks like friction is the only thing holding it in there.Last edited by gavztheouch; 15-01-2013 at 10:36 PM. Reason: add details

CNC routing and prototyping services www.cncscotland.co.uk

ADD ME ON FACEBOOKS

ADD ME ON FACEBOOKS

-

15-01-2013 #30

Surprise surprise.!! . . . I've been chastised many times or warned about possible Legal action for calling these machines and always replied " If it ever got to court then my Undefeat-able defence would be the machine it's self " . No court or Engineers report would disagree these machines are Bad and unfit for purpose.!! . . . . . .Totally disgusting the guy should be ashamed.

Just HOPE people looking to buy see this thread and take note.!!

Thread Information

Users Browsing this Thread

There are currently 4 users browsing this thread. (0 members and 4 guests)

Similar Threads

-

FOR SALE: Marchant dice cnc router mill compatiable with mach 3

By gavztheouch in forum Items For SaleReplies: 7Last Post: 23-03-2021, 12:59 PM -

BUILD LOG: A3 Marchant Dice Kit

By neo in forum DIY Router Build LogsReplies: 25Last Post: 03-03-2021, 11:54 AM -

Marchant Dice

By agent17 in forum Marketplace DiscussionReplies: 28Last Post: 06-06-2020, 11:06 AM -

Marchant Dice on eBay

By irving2008 in forum Marketplace DiscussionReplies: 4Last Post: 06-09-2008, 05:37 PM

Reply With Quote

Reply With Quote

Bookmarks