Thread: Renovating a Hardinge HLV-H

Threaded View

-

28-03-2009 #11

What a difference a day makes... (with apologies to Dinah Washington...)

Actually, the spindle motor VFD will also run the small motors quite well without complaint, Bill. I don't know how you intend to use your VFD, but I use mine 99% of the time to generate 60Hz (50 Hz in your case.) The remaining 1% is for a virtual backgear for slow threading or large faceplate work in stainless or other tough steels at 25-30Hz. That big super balanced motor is on a 5 hp frame and won't take overspeeding lightly.

I may have misunderstood the logic you described, but I believe I might rethink that approach. You absolutely want the ability to raise or lower spindle speed while the tool tip is cutting! I can't count the number of times just a small change in speed has stopped tool system resonance (skreeeeech) and resulting finish problems when turning a part or threading. I wouldn't give up that unique capability that Hardinge designed into the lathe for a thousand bucks.

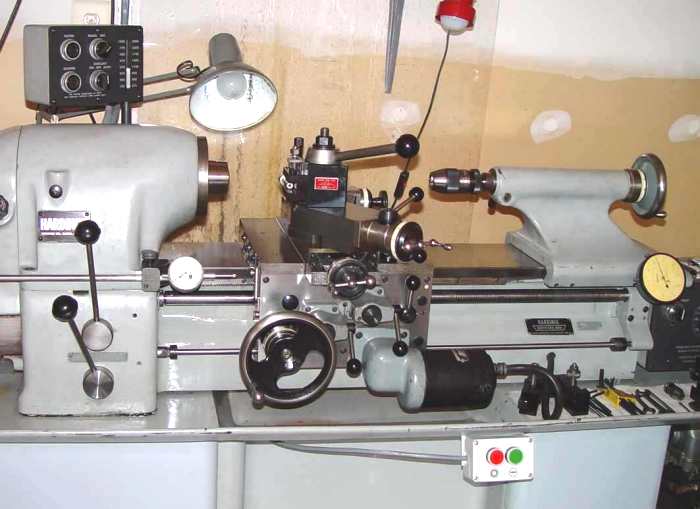

Here's a suggestion - just bypass the control transformer (feeding it from straight 415v), and hook up the VFD feeding everything else and give it a try. You won't have to change anything that way except the wires to the control transformer. Leave the high/low speed lever in the position you will use most of the time. Use a separate on/off pushbutton for the VFD like this one:

Try it...you'll like it... - Mike

- Mike

http://aafradio.org/

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

REBUILD: Hardinge HC rebuild

By northumbrian in forum Lathe Rebuild LogsReplies: 29Last Post: 21-02-2017, 12:07 PM -

Hardinge KL-1

By pauly45 in forum Conversion Build LogsReplies: 22Last Post: 18-10-2013, 07:31 PM -

WANTED: Hardinge hlv-h or Feeler 618

By cookie in forum Items WantedReplies: 1Last Post: 26-02-2011, 09:09 PM -

NEW MEMBER: Hardinge HLV-H Lathe

By Roger Williams in forum New Member IntroductionsReplies: 1Last Post: 25-08-2009, 01:56 PM -

Hardinge HLV-H manuals

By BillTodd in forum Milling Machines, Builds & ConversionsReplies: 13Last Post: 10-02-2009, 12:22 AM

Reply With Quote

Reply With Quote

Bookmarks