Thread: Renovating a Hardinge HLV-H

-

22-03-2009 #41

I mounted the DRO on the front of the bed.

I had to make a bracket to attach the scale to the apron. I didn't want to drill any more holes in the machine, so I devised a mount that would fix to one existing apron bolt and then clamp to the bottom edge.

I'm fairly pleased with the result; The rear clamp grub-screws area real pain to tighten, but once done-up the bracket is very secure.

Getting the armoured cable to roll with the movement of the carriage without getting snagged on the edge of the sump was a tedious job - In the end I had to add a perforated cable guide under the edge of the bed and a length of spring wire to the cable to keep it straight. I should be ok

-

23-03-2009 #42

A bit premature perhaps but, I thought I'd fit the doors

-

24-03-2009 #43

Applied power to the thing for the first time.

First I rewired the control transformer to accept 240v input (instead of 440) then checked the contactors were operating OK.

Checked the power feed controls - they were working OK, except I'd reversed the connections to the variable transformer so high speed was low and vice-versa (easily fixed).

I then bodged* my 440v VFD on, temporarily using the control transformer as a step-up. Got the spindle spining in both high and low speed and up & down the speed range.

But, while doing all this, I noticed the slow-start resister on the VFD was smoking (It's an old 5HP Toshiba device and has a softstart to prevent fuses popping on switch on). I powered down to investigate why the relay, which bypasses the resister, was not working. I had to take the VFD apart to find out why (I have no manual for this thing). I stuck it back together only to get no responce at all. I then realised I'd forgotten to replace the current limit lead (which has to be removed to get at the relay).

It popped a 600v 20A fuse and killed one of the IGBT modules :(

( a MG50M2CK1, if you have any in your pockets)

BTW Mike:

I found a couple of subtle differences between my machine and the wiring diagram from your site:

The spindle interlock contactor is wired in a different place it disconnects the 3ph only to the motor and the 1ph control power to the up/down contactors

A couple of spare contacts on the fwd/reverse switch are used to break the main contactor coil circuit - so if the fwd/rev switch is changed while running it stops the machine.

I'll draw a diagram of it for your site if you wish.

*(I do this sort of thing for a living, so by bodged, I do not mean unsafe)Last edited by BillTodd; 24-03-2009 at 10:05 PM.

-

24-03-2009 #44

I'm not surprised. That's one of the reasons that they have a pocket in the electrical door - to hold the as-built condition of the machine when it went out the door of the factory. That condition does change over time, usually in minor ways. I've also noticed occasional cultural differences in wiring design between the US and European models, mostly related to safety practices on each side of the pond.

I'd be delighted to put it up on the aafradio site as another variation if you'd like to e-mail it to me. Never can tell who it might help in the future.- Mike

http://aafradio.org/

-

27-03-2009 #45

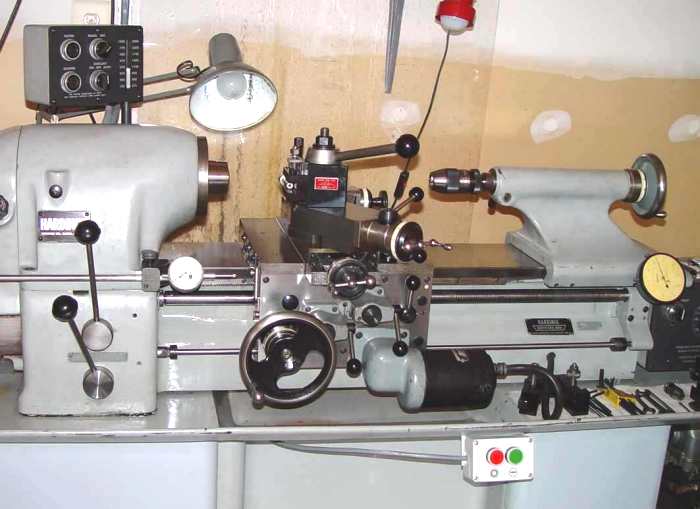

I had to finish the worklight before I could post these :)

Progress has slowed while I'm awaiting the 240-415v step-up transformer to arrive from Airlink Transformers. Meanwhile, I've found another, much smaller and neater, Variable Frequency Drive to power the main motor ( A 1500W Siemans MM150).

I'm bidding on a couple of low power (100W) VFDs to run the coolant pump and speed change motors at the moment, with the intention to completely rewire the control box.

The plan is to use the interlocked pair of contactors (currently used to control the speed adjust motor) as a new speed selector relay. This new relay pair will only change speed (thus disconnecting the VFD) when the VFD is stopped. I'll keep the original speed change lever and switch, but it will be used at 24v to control the VFD.

I could use a microprocessor to control all this but, at the risk of being called a luddite, I intend to use simple relays in the interest of fixability (by others).

I'll post a circuit when I've worked out the details.Last edited by BillTodd; 27-03-2009 at 08:22 PM.

-

28-03-2009 #46

What a difference a day makes... (with apologies to Dinah Washington...)

Actually, the spindle motor VFD will also run the small motors quite well without complaint, Bill. I don't know how you intend to use your VFD, but I use mine 99% of the time to generate 60Hz (50 Hz in your case.) The remaining 1% is for a virtual backgear for slow threading or large faceplate work in stainless or other tough steels at 25-30Hz. That big super balanced motor is on a 5 hp frame and won't take overspeeding lightly.

I may have misunderstood the logic you described, but I believe I might rethink that approach. You absolutely want the ability to raise or lower spindle speed while the tool tip is cutting! I can't count the number of times just a small change in speed has stopped tool system resonance (skreeeeech) and resulting finish problems when turning a part or threading. I wouldn't give up that unique capability that Hardinge designed into the lathe for a thousand bucks.

Here's a suggestion - just bypass the control transformer (feeding it from straight 415v), and hook up the VFD feeding everything else and give it a try. You won't have to change anything that way except the wires to the control transformer. Leave the high/low speed lever in the position you will use most of the time. Use a separate on/off pushbutton for the VFD like this one:

Try it...you'll like it... - Mike

- Mike

http://aafradio.org/

-

29-03-2009 #47No, it's my fault for not making it clear :)I may have misunderstood the logic...

For those unfamiliar with the Hardinge drive train; The lathe has a dual speed (480/1480 rpm - 0.5/1.5hp) three phase drive motor and a 8:1 variable V-belt system (driven by a motorised jack with up/down buttons - see attached picture) that gives it two ranges of 125 to 1000 and 375 to 3000rpm.

The dual speed motor is controlled directly by a lever switch giving Low/Stop/High speeds. The motor is sufficiently robust to withstand the current surges caused by abrupt speed changes when connected to a three phase supply. (i.e. it is possible to switch high>Low or Low>High without stopping)

I'm going to drive my main motor from a 1.5kW electronic variable frequency drive (often called an inverter or a VFD). These convert the single phase mains to a variable frequency three phase. They can ramp the motor speed up and down, slow it quickly with DC injection braking and all sorts of clever tricks.

I want to keep and use the Hardinge Low/Stop/High Lever control. However, the VFD will not take kindly to the power surges if I leave it connected as it it now - it will just stop with a fault code or worse, go bang.

I will switch the motor connections to the VFD with a dual contactor (one for high one for low), changing the range only when the VFD says it is at 0Hz (stopped). These contactors have to be a mechanically interlocked pair to ensure that both cannot be 'ON' at the same time. These are a fairly expensive and awkward to find item . Fortunately, there is already a pair of these in the control box, used to control the variable speed jack. I'll use another small (100W) VFD to drive the jack up and down.

The main VFD has enough power to drive both the jack and the main motor. However, using a separate VFD for the jack means I can also dispence with the fwd/rev contactor allowing the main VFD to reverse without upsetting the jack motion.

I'll make a simple control circuit* (it only needs to be two small relays) that will take the input from the existing lever switch. If/when the lever is moved directly from one speed to another it will; tell the VFD to STOP, and once the VFD says it is at 0Hz (stopped) it will change the range contactors then tell the VFD to ramp back up to speed (50Hz).

I wont be using the VFD to change the motor speed, it'll simply start,stop and reverse it smoothly [although, as you say Mike, using it as an electronic back gear might be useful]

*I cut my teeth on a microprocessor controlled motion sensing logic for a 24trk tape recorder, but I don't want it to make this that complicated.

----------------------------------------------------------------------------------------------------------------------

Yesterday I tested the new VFD. Typically, after searching everywhere to find a cheap step-up tranformer and ordering a new one (80 sobs! :(), I remembered I had a 1kVA tranformer that would do the job perfectly !!! (Kip, of this parish, will be laughing at this point because I sold him the other one of the pair I had)

It took about a hour of playing with the up/down speeds, adjusting the brake, oiling the pulleys etc. to get the lathe to run smoothly. The attached picture shows a penny balanced on the head stock while the spindle is spinning at 3174rpm, unfortunately the camera flash has frozen the motion.Last edited by BillTodd; 29-03-2009 at 09:35 PM.

-

29-03-2009 #48

Mike,

Here's the original wiring diagram in PDF format (hope it's not too big for your site).

Bill

[edit] pdf updated - spindle interlock correctedLast edited by BillTodd; 31-03-2009 at 01:49 PM.

-

30-03-2009 #49

Great work Bill, I jumped over here to see your work after reading your posting on the PM site about your vibrating collet closer. I can't believe how well you got the rusty steel components to "clean up".

I love Hardinge lathes. I have (2) HLV-H's, (1) HLV-TFB, & (2) HC's. I also have the Feeler clone of the HLV-H:). It's a disease I tell ya!

-

30-03-2009 #50Thanks Jim :) (I'll pick up the collet closer thread on PM)Great work Bill, I jumped over here to see your work after reading your posting on the PM site about your vibrating collet closer.

I think I'm lucky it was so cover in filth (congealed coolant) is has to a large extent protected the steel from the weather.I can't believe how well you got the rusty steel components to "clean up".

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

REBUILD: Hardinge HC rebuild

By northumbrian in forum Lathe Rebuild LogsReplies: 29Last Post: 21-02-2017, 12:07 PM -

Hardinge KL-1

By pauly45 in forum Conversion Build LogsReplies: 22Last Post: 18-10-2013, 07:31 PM -

WANTED: Hardinge hlv-h or Feeler 618

By cookie in forum Items WantedReplies: 1Last Post: 26-02-2011, 09:09 PM -

NEW MEMBER: Hardinge HLV-H Lathe

By Roger Williams in forum New Member IntroductionsReplies: 1Last Post: 25-08-2009, 01:56 PM -

Hardinge HLV-H manuals

By BillTodd in forum Milling Machines, Builds & ConversionsReplies: 13Last Post: 10-02-2009, 12:22 AM

Reply With Quote

Reply With Quote

Bookmarks