Thread: Bearing fit problem

-

04-10-2013 #1

Hello all,

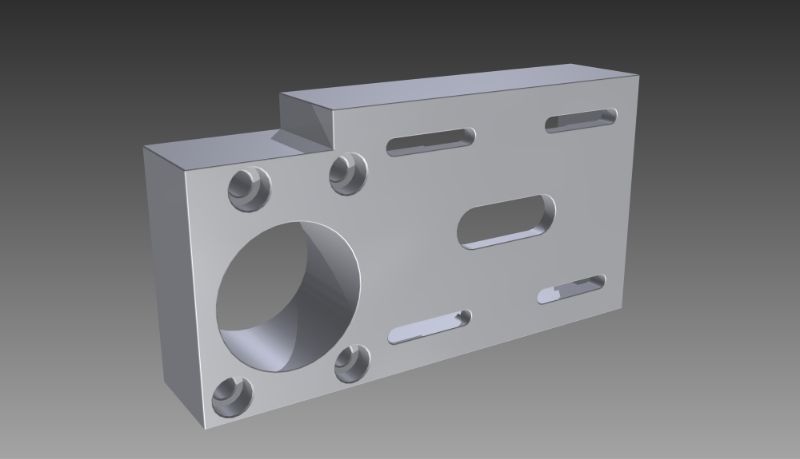

I want to fit the bearing in image in the 40 mm thick aluminium plate. I am thinking to heat the aluminium to have 80°C temp difference. But I have no idea what size to bore the plate. I am thinking at about -0.04/-0.05 mm.

I want to use the following method posted by Jonathan:

Just need to find the "appropriate amount". The bearing needs to hold up axial load as it will be used for a rotating ball nut.When boring something for a bearing on the lathe, for myself, which requires a press fit I slowly approach the required diameter and machine the first few millimeters of material to the size where the bearing only just slides in. Then back off the appropriate amount for the press fit and machine the rest of the hole

Best regards

EDIT:

Just realised that the motor will transfer the heat to the plate and the expansion difference between aluminium and plate will loosen a little the bearing. I need to fit the bearing so tight that at -10°C the aluminium (6063) will not crack.

Or should I look for another mounting design?Last edited by paulus.v; 04-10-2013 at 08:49 PM.

-

05-10-2013 #2

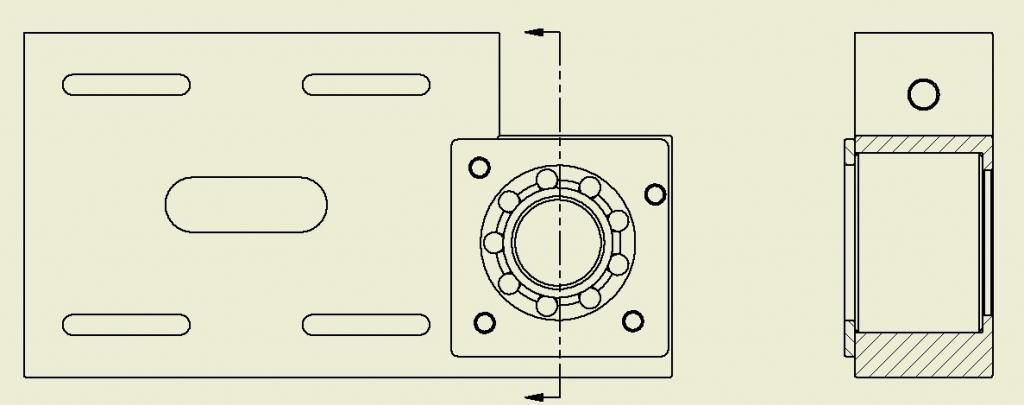

If it needs to take axial load, then a press fit alone is not ideal, so it would be best to redesign it to use some form of plate to clamp the bearing in place.

-

05-10-2013 #3

As said above, you need to stop the bearing moving under axial load. If the axial load is in one direction only, you could get away with leaving a 3mm step on one face so that the bearing presses in but ends up flush on one face? Failing that, you'll need a step and an internal circlip. Or a circlip either side. Or a step and a stepped shaft. Or...

-

07-10-2013 #4

Thank you for your replies.

I ended up with this

... but my question still remains. As the plate gets hot from the stepper, assuming a 50°C temperature change between assembling and max. operating motor temp., the difference between aluminium and steel (bearing) expansion will be 0.02mm. As I don't want to end up with play I need to use heat mount but I'm not sure if -0.05mm for the hole is fine or should I try with more? My only concern is the elasticity of the aluminium..

-

07-10-2013 #5

I think you're over thinking this.

Provided the retaining plate actually presses against the bearing and holds it in the housing, then there will be enough give in the plate for what is a very minimal amount of expansion.

-

08-10-2013 #6

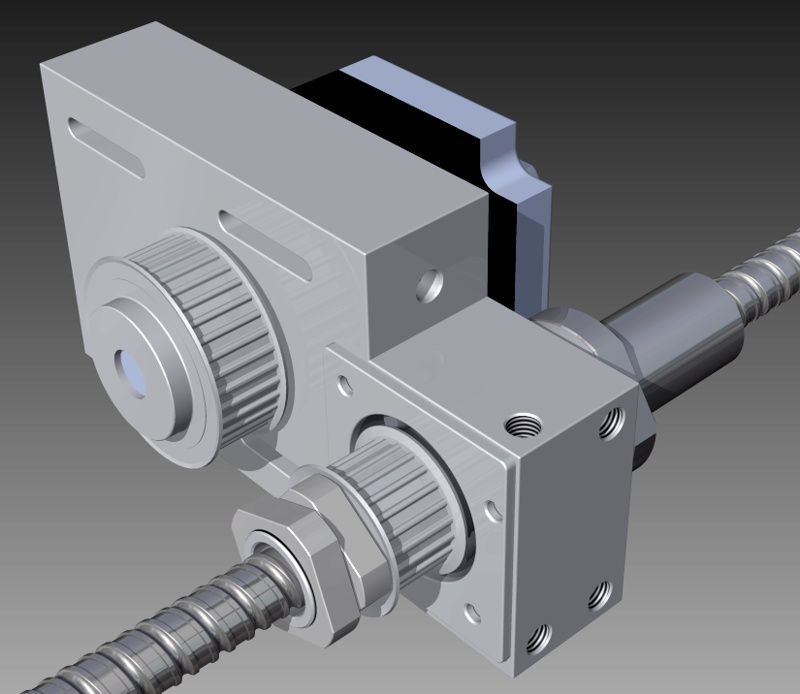

It looks like you're using a double row angular contact bearing, although the dimensions aren't standard 5205. The problem with most double row angular contact bearings in this application is they have a small amount of clearance, so there will be axial play. Not much, probably not a big deal if you're just making a router to cut wood, but if it's any machine more serious than that you'd be better off going for two bearings so they can be preloaded. You'll also get a stiffer arrangement using a pair, as they can be spaced out further, which will help increase the critical speed of the assembly - again important as that's probably the reason you're making this.

-

08-10-2013 #7

It's a preloaded rear wheel bearing, so there will be some play, and in this application probably more than the specified amount as they're designed to be clamped onto a stub with a reasonably high torque setting to clamp things together.

-

09-10-2013 #8

Yes, first I made the design with a pair of bearing but I ended up with this because the workshop where I make the parts does not have precision machinery and the bearing alignment would have been difficult. Even with this design I fear about pulleys alignment. I don't get why the spaced bearings will increase the critical speed?

The bearing is a Renault rear wheel with balls (most of the makes are with roller). There are two inner rings so if there will be play I can take one out and grind the inner face and then preload like a pair of ac bearings. Am I correct?

Here is the entire assembly. Tomorrow morning I'll go to machine them

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

We are Bearing Station: Ask us anything!

By Mark Proctor in forum Marketplace DiscussionReplies: 11Last Post: 04-12-2013, 11:01 PM -

Bearing Blocks

By GTJim in forum Rails, Guideways & BearingsReplies: 1Last Post: 15-01-2013, 07:18 PM -

FOR SALE: bearing/belts

By oadamo in forum Items For SaleReplies: 9Last Post: 03-01-2011, 12:43 PM -

FOR SALE: Linear rail and bearing

By black5f in forum Items For SaleReplies: 5Last Post: 02-07-2010, 07:23 PM -

eccentric bush for bearing

By adscnc in forum Gantry/Router Machines & BuildingReplies: 0Last Post: 18-09-2009, 04:53 PM

Reply With Quote

Reply With Quote

Bookmarks