Thread: Bearing fit problem

Threaded View

-

09-10-2013 #8

Yes, first I made the design with a pair of bearing but I ended up with this because the workshop where I make the parts does not have precision machinery and the bearing alignment would have been difficult. Even with this design I fear about pulleys alignment. I don't get why the spaced bearings will increase the critical speed?

The bearing is a Renault rear wheel with balls (most of the makes are with roller). There are two inner rings so if there will be play I can take one out and grind the inner face and then preload like a pair of ac bearings. Am I correct?

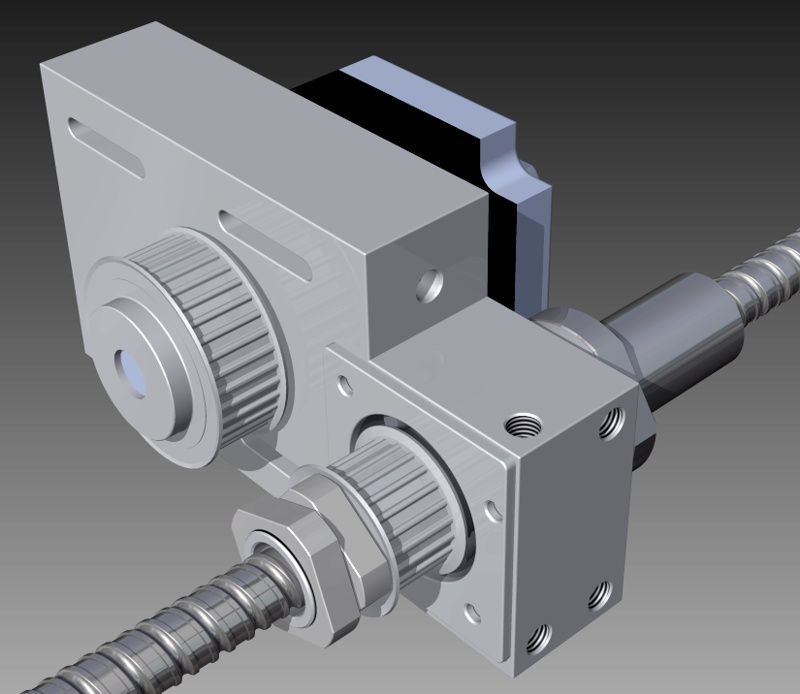

Here is the entire assembly. Tomorrow morning I'll go to machine them

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

We are Bearing Station: Ask us anything!

By Mark Proctor in forum Marketplace DiscussionReplies: 11Last Post: 04-12-2013, 11:01 PM -

Bearing Blocks

By GTJim in forum Rails, Guideways & BearingsReplies: 1Last Post: 15-01-2013, 07:18 PM -

FOR SALE: bearing/belts

By oadamo in forum Items For SaleReplies: 9Last Post: 03-01-2011, 12:43 PM -

FOR SALE: Linear rail and bearing

By black5f in forum Items For SaleReplies: 5Last Post: 02-07-2010, 07:23 PM -

eccentric bush for bearing

By adscnc in forum Gantry/Router Machines & BuildingReplies: 0Last Post: 18-09-2009, 04:53 PM

Reply With Quote

Reply With Quote

Bookmarks