Thread: I want a vacuum table!

-

24-10-2013 #11

Ahh I think I've just had a great idea about how to do this :)

The bed of my machine is currently built from strips of 10mm HDPE with 40mm box section steel below it. Between the strips is 40mm T-slot alu profile. The alu is there obviously to allow easy clamping and the steel just to give strength.

The HDPE is not only screwed into the steel and alu but also bonded with 'green glue' which is an elastic damping glue, seemingly much like silicon sealer.

So my idea is to put end-caps on each of the steel box sections and drill some holes up to the HDPE to suck vacuum. There will of course be leaks in the steel section where there are a few screws. The existing screws up to the HDPE don't matter since it will just help to suck down any work like the open holes I will make. On the under-side of the steel box section there is a nut and bolt at each end and also two directly tapped screws in the middle. The nuts at each end shouldn't leak a lot because they tighten down nicely on the steel and I could smear some silicon around it. The directly tapped screws in the middle might leak and I can only think of inserting them with some teflon tape, but only being two per box section I can't imagine it will allow much air flow.

So, I would then have a vacuum being drawn directly from my existing HDPE bed on which I can route some channels to spread the vacuum and possibly take a gasket.

If this works it would be great because not only do I already have most of the work done, I get the strength of my existing steel and alu supported bed. If I wanted I could still place a sacrificial board on top and pull a vacuum through that if I had a proper vacuum pump. Having watched a few videos I know I'd need to seal the perimeter of the MDF board and skim the top and bottom. I'd need to do each strip separately though or the air would come through the bottom of the board from the T-slots.

I may need to find a way to plug the holes for when I use flood coolant. At the moment the coolant gets channelled into the T-slots which I blocked at the ends and goes down a little drain.

Here is my existing bed.

Last edited by Tenson; 24-10-2013 at 08:25 PM.

-

24-10-2013 #12

the vacuum doesnt pull the paper into the holes, and after the cut has been made it continues to hold the material perfectly still. Clear / Paper Roll Or A4 Sheet Of Application Transfer Tape Many Sizes App Tape | eBay. Ive not tried this but just sourced it today.

alex

-

24-10-2013 #13

Oh, I think that is what I'd call masking tape?

-

24-10-2013 #14

its similar to masking tape, its used for applying to vinyls that are then applied to signs/vehicles ect, then the backing paper is removed, leaving the vinyls in place. I found it a great help.

-

12-11-2013 #15

What do you chaps think about this pump? 8.0CFM 5Pa 250W REFRIGERATION AIR CONDITIONING VACUUM PUMP + GST | eBay

It says 8CFM (240L/Min) which is about twice the other pumps I've found on eBay and it's less expensive too. Too good to be true?

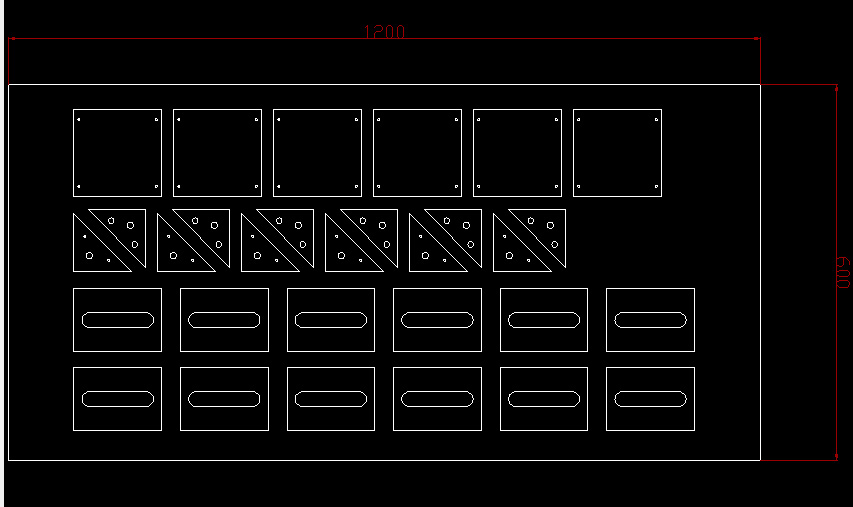

Can anyone say from experience if I wanted to cut out these parts below with a 3mm cutter, what sort of flow-rate do I need from a pump to maintain a good 'suck'? If I were cutting soft materials I could leave a very thin skin to keep the vacuum up, but I often work with cast acrylic and I don't imagine I can 'skin' that so cuts would need to be full depth. The advice above of using adhesive backed paper may help me here but I just want to get an idea about flow-rate.

free uploadLast edited by Tenson; 12-11-2013 at 06:15 PM.

-

12-11-2013 #16

Tenson, even with a good vacuum, there may be a tendency for small parts to move after they are cut out. Leaving a couple of small tags where necessary does work wonders. with some plastics sometimes they try to partially weld themselves back together. I find that "climb milling" will usually ensure that the weld sticks to the scrap rather than the cut item. I am afraid that I can't give you any figures for the vacuum - suck it and see!!! G.

-

12-11-2013 #17

I'm not sure I can really do tags, I need good clean cuts on all parts but acrylic has a tenancy to shatter if cut with clippers for example, which is how I imagine removing the tags then a bit of sanding.

At any rate, is there an easy way to leave tags using Dolphin PartMaster? Drawing all the tags in CAD seems a pain because something like a square cutout becomes 2 or 4 separate cutting paths.

-

12-11-2013 #18

I use a commercial program (Alphacam) and it will allow the tabs to ramp up and then down. This just lifts the Z axis during the the normal X Y travel and does not require any extra cutter paths. If I don't ramp then it does stop at the start and end of the tab and uses additional cutter paths. I keep tab lengths and height to top of tab to the minimum and and can usually remove the tab with a sharp knife. Some sanding is required (not much), but this is far better than losing the part. Carefully placed double sided tape is my own alternative to tabs, but can be difficult to remove. A vacuum bed is really good, but small components are sometimes a problem.

-

12-11-2013 #19

Tenson

I have just hunted out the manual for my Hydrovane compressor, it has a 2.2kw motor and knocks out 9.5CFM @ 100 psi so probably 30psi if sucking would increase the capacity(sure someone on here could do the calcs) but i can't see that e-bay pump knocking out 8CFM and don't forget that's free air delivery once you get it loaded that figure will drop. Hope i am wrong as i just had a look on e-bay & it looks like someone has just bought one.Just my thoughts.

regards Mike

-

13-11-2013 #20

Hi All

I suspect 2.2 KW is only sufficient for a very small Table

I recently visited a factory with a commercial router table with vacuum hold down. The noisiest machine in the factory was the 20HP vacuum pump under the table. Conversation near it was very difficult.

Regards

John

Understanding Vacuum Hold-Down

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

vacuum table using compressed air

By plasticman in forum Milling Machines, Builds & ConversionsReplies: 6Last Post: 25-12-2012, 05:42 PM -

Vacuum Table Advice

By Minium in forum Milling Machines, Builds & ConversionsReplies: 13Last Post: 13-11-2012, 09:52 AM -

Custom Vacuum Table 'Hold Down' System - piping/valve advice

By FlightCaseCo in forum Machine DiscussionReplies: 4Last Post: 16-01-2012, 06:56 PM -

Much advice needed for an 8' x 4' cnc router project / and vacuum table

By FlightCaseCo in forum General DiscussionReplies: 1Last Post: 01-01-2012, 12:34 AM -

DIY Vacuum Table

By templecorran in forum Machine DiscussionReplies: 18Last Post: 10-11-2010, 12:11 AM

Reply With Quote

Reply With Quote

Bookmarks