-

05-03-2014 #1

Hi all,

Consider this my introduction, im Phil, from Kent uk and have a cabinetry workshop producing all kinds of cabinets. I was looking to buy a second hand CNC router but decided i wanted to be the service provider for my own machine, not sub contracting servicing to a manufacturer.

Anyway, i want to build a gantry machine, it will be MDF torsion box based bed as i know i can build one dead flat. I have the design of the actual build nearly done, just working on getiing my head around the electrics, method of moving the axis about, and understanding how all of that works.

I want to build a machine that can take half standard sheets, so 1220 x 1220 in all, i was up for producing a full size machine, but not 100% sure if it is the right thing to do, obviously that would be my ideal, but the thought of a full 2440x1220 working area seems as though i would encounter issues with tolerances etc, however, if it is what i would ideally like, might i not as well go for it?

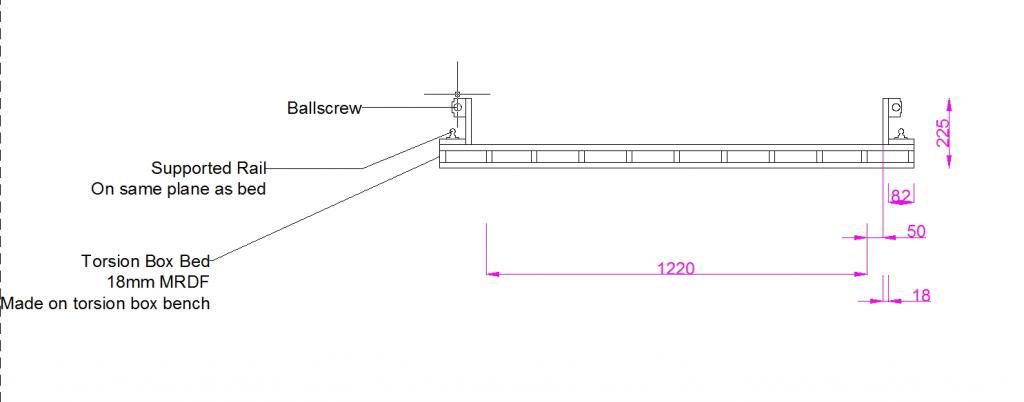

Here's the design, bit different to everyone elses drawings, i am a 2d CAD man, so bear with me. It is not complete, and i am just understanding the rail types etc so not got much further than that yet.

Ok this is the basic end view of the bed, comments welcome, but bear in mind, i am not familiar with all of the lingo so treat me like an idiot.

the support under the bed is likely to be light construction steel/alu framework as the bed will be very rigid in itself, basically zero flex/sway leg structure to support the loads above, lots of diagonals, lots of solid joints, nice and level, with levelling feet

this really is the first draft, but i need help, and there is no place better than here right?

will be running steppers, not sure on how to do drivers, controllers etc, my friend suggested to ask if i could use RPI (raspberry p i ) i dont know how but it is a great system/component from what i hear.

Also with regard to actually drawing designs to cut, i use CAD currently (drawing above is just a quick draft) is there a way to use CAD drawings/dwg files with a cnc through the other programs like MACH3 and Linux CNC?

-

05-03-2014 #2

Hi Phil,

Ok well I'm going to start by trying to talk you out of building main base with MDF, yes I know your familair with it and used to working it plus it's cheap and all that but it's also Rubbish for building CNC machines from.

The torsion box design will help but still MDF is rubbish due to fact it expands and changes shape(Even when sealed) which is not what you want with a CNC machine. If you must use Wood or wood based products then go with decent quality plywood and just use MDF for a spoil board that you can surface every other day or when badly chopped up.

To be honest other than lack of familiarity with working with it then building frame from steel gives a much better machine and stable machine that doesn't cost the earth. If you want a proper machine that will last, stay stable and accurate for many years not just many months then go with steel.

Regards the electronics then forget the rubbarb pie other wise your on a hinding to nothing and will become very frustrated. The electronics on a CNC machine are very important and trying to cut corners here only leads to frustration and extra expense when you scrap them at later date when you see the light.!!

Best advise is DONT buy anything until your sure it's what you need and will do the job, BY FAR the single most common mistake is buying wrong electronics and motors for the job.

Building a CNC machine is best done with a step by step approach with each step guideing you on the next and electronics is well down the list so don't go rushing into buying any.

Regards Software then MAch3 and Linux cnc are both just Control software, that means they only control the machine and all it's functions. They don't do anything other than follow a set of instructions known has G-code or commonly called toolpaths output from CAM software in the form of a G-code file and watch and monitor Input signals, E-stop and limits switches etc or turn on or off output signals to control external devices like Vacuums etc.

To convert your CAD files into Toolpaths and prodcue G-code files you need CAM software, here you set the cutting parameters ie: Tool size, speed, depth etc and select profiles or geometry to follow.

There are many CAM packages ranging from Free to £££££ just do a search on the forum and you'll find many posts about whats available.

Hope this helps and just ask about anything your unsure about and don't be afraid to ask just because you don't know the lingo, if we don't follow what your meaning we'll let you know.Last edited by JAZZCNC; 05-03-2014 at 09:07 PM.

-

05-03-2014 #3

That's good advice so far. What should be my first step then? I think I have the basis for a design, I was set on a disposable top anyway so that's a consolation. What do I use for a bed then that will cost the same money as MDF

-

05-03-2014 #4

I have a CNC router made from MDF. It's essentially a JGRO design (lots of info available via Google) but slightly expanded to give a cutting area of something like 800x400. It uses a torsion box braced structure as a bed. The only way I would use MDF again is if the bed was on a strong metal (steel/aluminium, doesn't matter) base and well-supported. In which case, why bother with the torsion box, and just use MDF as a spoil board directly on the support structure. In fact, exactly what Jazz has suggested. I can't imagine an MDF structure of the size that you are talking about maintaining any kind of accuracy, even if you can get it flat to start with. I started a thread recently about cutter accuracy, as it seemed as if a 3mm cutter I was using was behaving as if it were about 2.3mm in diameter. The answer was that the machine was bending by the equivalent of 0.35mm when it was taking a cut. Heavy cut? Well, if you think that a 3mm cutter with 1.8mm depth of cut in MDF is heavy cutting...

My next machine (I'm working on design ideas at the moment) will be welded steel. If you have access to welding facilities, steel is not that expensive, and in any case it's the bearing rails, ballscrews and nuts, electronics, etc that are the biggest cost in building. It's not worth taking a short cut to save a few quid on a machine that you will want to earn its keep reliably and consistently.

Raspberry Pi? Yes, they're cheap, and great fun to play with. But they are based on a small, cheap, slow mobile phone processor. It's not obvious at first but what you need is a machine that can handle realtime computing - the job of the computer is to send pulses very fast and with accurate timing to the drive electronics, and that's not even the same as a fast processor. My son has just bought a motherboard for £85 including processor and memory that outperforms (in terms of realtime computing) the PC I use which has, in theory, a faster CPU. You could build a PC based on that motherboard for under £200 that would be a pretty good start, whether you put on Windows and run Mach3 or Ubuntu and run LinuxCNC.

As far as finding a starting design on this forum - good luck! Every so often there's a discussion about having some kind of communal design as a reference, but you won't find two people who will even agree on the basic cutting volume for it, let alone material, cutting speeds, etc! However, there are a number of designs being discussed in the "build logs" area and you should take a look at some of the active threads there that might give you some good ideas about where to start.

-

05-03-2014 #5

Ok well thats the problem isn't it nothing will be better and cost same.!!

The problem you have is stabilty of the surface that important components like linear rails fasten on. Because you plan to use a Torsion box design the strength and flex will be reduced but you won't be immune from material expansion and MDF expands if you so much has show it a cup of coffee. Now your problem will lie with the fact your mounting the rails directly onto the torsion box so if this material deflects or expands the accuracy of the machine changes as the rails are no longer on the same plane.

For this reason your better with a metal frame work for the machine and mounting important stuff like rails, ballscrews etc as it doesn't expand with moisture and less with heat. It's also much stronger will take much more abuse over a much longer time period.

Now the Don't get me wrong I'm not saying you can't get a accurate machine when building with wood, esp when built for cutting wood which requires low tolerences, but unless lots of effort and special techniques are employed in the build you'll spend a lot of time chasing accuracy and keeping accuracy.

The effort required and time required are IME not worth it and in the long run you'll spend just as much money if not more than if you built it from Steel box section. The differance will be very much worth the effort and you'll have a machine that will last for years and if carefully built with correct components give hassle free usage.

Often you can return your investment or very large portion of it when ready for bigger or better machine which you certainly won't if built from wood.

The starting point is where your at now.? The Design.!!

Spend some time looking at designs and sketching designs that you feel are within your skills and abilty's. Don't be afraid of stretching your skills, you'll be amazed what your capabale of and the rewards are very nice but do be realistic.

Don't let welding put you off has where not designing nuclear reactors or needing sky scraper strength welding and just cheap MMA(ARC) welders are more than enough along with short welds. Pigeon Shit welds are often good enough and with quick grind and lick of paint they disappear.!

You have most the basic information you require, like Size required and Materails your mostly going to cut, so now you just need to identify machine design style and select the best components for the machine at this size.

Your biggest and most important choice at this size is whether to use Ballscrews or Rack & pinion for linear motion.? This will also to some degree dictate the design slightly to accomodate which your using.

Ballscrews are more efficient and give best accuracy but at this length your near the limit and in danger of whip if not correctly sized. Rack & pinion is better for longer machines but requires more power has it's less efficient and for this reason it uses gearing ratios so theres slightly more work involved.

I suggest you stay away from flat Plate and Skate bearings type of linear rails and unsupported round type rail. Only use supported rails.

Don't get obsessed with rapid speeds or building light weight gantry's. Fast rapid speeds are only of any use on very large machines or where lots of point to point work like drilling 1000's of holes are needed, most of the time the machine will be cutting much slower and it's this cutting speed that matters the most.

The strength and ridgidty of the gantry is important and often with these comes weight but to a point that can be a plus and allow deeper cutting and better finish. Obviously Gantry weight does have to be considered but upto about 70-90KG then your fine with most stepper systems.

Think that's enough for now but I suggest you look around the forum at similair sized machines, you'll also motice there are not too many built from wood.? and for good reason.

Hope this helps.

-

06-03-2014 #6

Thats cool, i appreciate honesty from experience. I can weld, i use a MightyMig 170 so the steel base will not be a problem, i was intending to do that from the outset. Working bed wise, what should the solution be? i chose moisture resistant MDF as it is alot more stable, and i dont want to go on and on about MDF but i have around 30sheets a month come through my shop so it seems crazy not to use it for the major parts.

Can i use the torsion box on top of Steel framework to better effect? i will be laquering the bed and all/any MDF components, IME they would be highly unlikely to swell or expand once this has been done and i have been working with it for years, tolerance wise any expansion would be 0.05 on its thickness over 5 years. But as i said i do value opinion and experience, so if you have or any other users had a moisture resistant MDF bed, laquered etc, and it was still subject to expansion then i would definitely like to hear exactly how it occurred and what the stimulus was for the change/expansion. I am not saying you are wrong JAZZ at all, i am glad you raised the potential issue. But i wouldnt use it if i wasnt sure. Most people use ali tables but this is mega expensive and i need to keep budget low, obviously i am thinking about quality as a paramount, and the initial decision for an MRMDF bed was not a light hearted one as i have not seen a lot on here.

All above set aside though, if i do choose 2400/2500mm for X, then i would probably have to look at a more suitable solution as i think over that distance there is likely to be creep and settling etc. So if i go half sheet, i think i would chose MDF torsion, but full sheet will need an alternative, suggestions anyone? i will still be using a disposable bed.

I was looking at square rail and HWIN carriages last night, as opposed to round supported rail, again cost was forefront in this option, it works out cheaper for the longer lengths, which might help if i do tackle a full sheet machine.

Gantry wise, i have sketched this up on paper but not drawn it on cad just yet. I was aiming for the sides to be Alu laser cut, then a torsion box beam for the Y axis rails to run off, again HWIN and square, then Z axiz pretty much similar across everyones machines with round rail and screw.

Motion wise, X and Y im not at all sure what to do. I think Y could benefit from screw, but X if it is 2400/2500mm long, i think whip as mentioned is the issue. As i am beginner to screw drive, and rack & pinion, maybe i should just bite the bullet and go for r&p as suggested. The other option i thought of was running it via belt fixed at a point to the gantry and a pully at either end of the X axis. This could run both sides of the gantry off one central motor but i also thought this would have low tolerance, when thinking about belt stretch, slip, etc.

What is my options for X motion, is it just R&P? I cant really see any other suitable way.

-

06-03-2014 #7

Question is what is your budget? Just spent 10 mins knocking up a quick design on Sketchup and I reckon you can build the base out of one 7.5m length of 100x50x4mm, one 7.5m length of 50x50x4 steel and one 3m length (chopped into 2 x 1.5m lengths) of 100x50x6mm Ali plus a spoil board of either MDF or Ply. With a length of 1.6m you could just get away (I'm sure Jazz or someone else will confirm) RM1610 ballscrews and 3Nm Nema 23 steppers. If you were frugal it could be done for approx. £2k with half decent electronics (like AM882 drivers, PDMX126 BOB, home made PSU etc.) and second hand (from fleabay) THK or NSK linear rails.

I've not drawn everything in, but it should give you an idea. The frame/bed will need more bracing and supporting but you'll get the idea from the sketch...

-

06-03-2014 #8

i could do 2K, it would be a well used tool in my workshop so if needed i could push the budget further. that design is exactly what i intended to draw but i have no experience of machine design. thanks for spending time drawing it, i didnt expect anyone to go that far. amazing help.

where can i read simple info to help me understand the mechanics behind it all? i have unanswered questions, like how to set up a stepper to drive the x, and how long is the belt going to be to fit exactly, or do i make an adjustable mount for the stepper to tighten the belt up once fitted?

if i were to produce a full sheet cutting bed, what would i use instead of ballscrews, and how do i work that out or are there examples on other build logs that you can point me to?

-

06-03-2014 #9

Have a look in the Router build Log section, there's lots of builds there. Some good ones to look at showing what equipment they used...in no particular order...

http://www.mycncuk.com/forums/gantry...-building.html

http://www.mycncuk.com/forums/gantry...eady-eddy.html

http://www.mycncuk.com/forums/gantry...g-machine.html

http://www.mycncuk.com/forums/gantry...ation-cnc.html

Irving's motor calculator to size the stepper motors you need: http://www.mycncuk.com/forums/machin...do-i-need.html

Control box/electronics/diagrams:

http://www.mycncuk.com/forums/genera...outer-cnc.html

Eddycurrent's build log has his electrical schematic in it http://www.mycncuk.com/forums/gantry...html#post52213

http://www.mycncuk.com/forums/genera...ic-advice.html

There are lots more if you search through the forum but those should give you something to go at......

-

06-03-2014 #10

This web site gives a decent overview of things.

DIY CNC: Build Your Own CNC, CNC Router, or 3D Printer

Be careful now , some people say this is OTT but I'm not really using anything special.

Last edited by EddyCurrent; 06-03-2014 at 04:53 PM.

Spelling mistakes are not intentional, I only seem to see them some time after I've posted

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

NEW MEMBER: What to buy when starting out

By smith99 in forum New Member IntroductionsReplies: 18Last Post: 11-04-2014, 01:13 AM -

BUILD LOG: starting from scratch- router 1st project

By idefix in forum DIY Router Build LogsReplies: 24Last Post: 10-01-2014, 12:53 AM -

NEW MEMBER: Complete beginener starting to learn

By johnd in forum New Member IntroductionsReplies: 1Last Post: 05-04-2013, 11:10 PM -

Need advice on starting my own machine shop.

By newtoid1986 in forum General DiscussionReplies: 16Last Post: 04-10-2011, 10:35 PM -

BUILD LOG: new build just starting

By dickieto in forum DIY Router Build LogsReplies: 5Last Post: 26-12-2009, 02:49 AM

Reply With Quote

Reply With Quote

Bookmarks