-

14-09-2014 #1

I bought my 2.2kw spindle & VFD in March from wholesalermultifunction (UK), installed and test it only with no load. Yesterday I started my first project and after some simple tests in acrylic with a 4mm 2-flute end-mill some sparks and smoke escaped from the VFD and both 16A fuses tripped. After that it started normally but only until I pressed the spindle run button. Another round of sparks and smoke with no fuses tripped and this time it was dead.

I followed the VFD setup parameters from the forum and checked them twice. The only difference is that I connected the mains to S and T instead of R and T but the manual says that I can connect to any of the three.

Any thoughts? Do I have any chance to have it replaced? Could have been my fault somehow?

Paul.

-

14-09-2014 #2

When you say you tested it with no load ? does that mean you started it with no motor connected?

-

14-09-2014 #3

No, running the spindle with or without any tool inserted and without machining any material.

And yes now I remember that when I connected the water hose some days ago I forgot to reconnect the motor power plug and started it for a few seconds without the motor.

After that it has run ok for about half an hour until I have applied some load (4mm end mill 3mm deep in acrylic), the bit didn't broke and the cut was clean.

-

14-09-2014 #4

How long is the cable between vfd and motor ?

Edit: I see from a previous thread you mentioned 5.5m, that should not cause any issues. Long cable runs could give you flames at the vfd.

Whats the full model number of the vfd ?

I think those red wires in the photos are the ones leading down to U,V,W terminals so my advice would be to check the spindle motor wiring for short circuits. This could be either inside the motor windings, the plug/socket on the motor, the motor cable.

Before you do anything, disconnect the wires from the U,V,W terminals and check the wire using a multimeter on ohms. This is because sometimes if you start at the motor end, just moving the wires can take the fault away and you will think it's fixed. With the meter connected move the wires around to see if a short circuit comes and goes, it could be between any of the three wires.Last edited by EddyCurrent; 14-09-2014 at 02:14 PM.

Spelling mistakes are not intentional, I only seem to see them some time after I've posted

-

14-09-2014 #5

Looks like you have done nothing wrong and I wouldn't mess around with it just send it back.

These things are mass produced to lowest price possible so things like this happen all the time, it's just a chance you take with cheap chinese stuff and they won't argue provided it's still within warrenty.

Next one could work flawlessly and never miss a beat It's just a lottery unfortunatly but they are so very cheap you can't buy anything in UK that comes remotely near.! . . . . If down time is important then buy a decent VFD now and keep the replacement for a spare.Last edited by JAZZCNC; 14-09-2014 at 06:01 PM.

-

14-09-2014 #62D / 3D CAM Software and CNC controller: http://www.estlcam.com

-

14-09-2014 #7

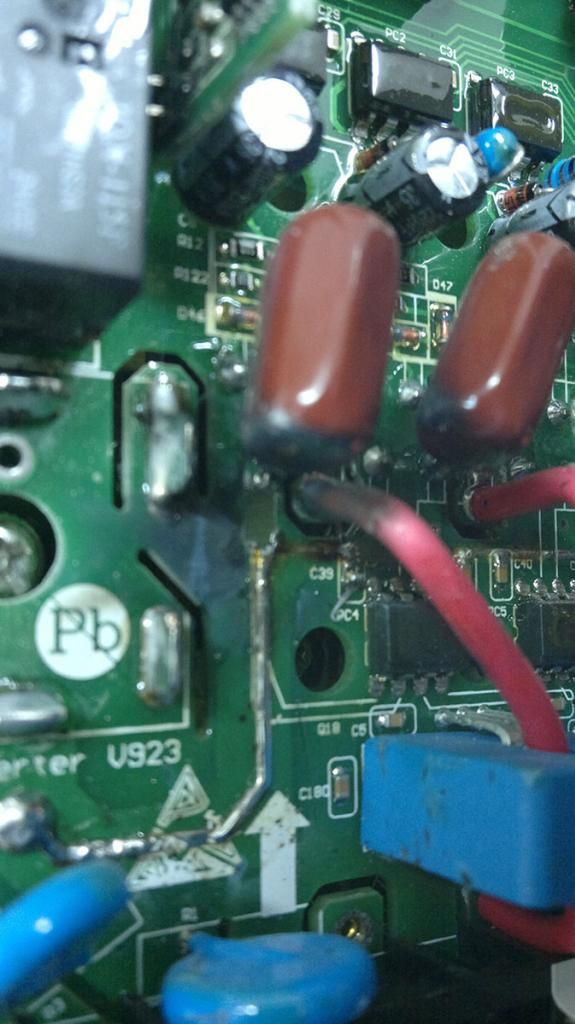

Where it says, Pb , that's the 3 phase bridge rectifier off the incoming supply. It looks like the negative PCB track for the DC link has suffered, or the rectifier terminals have shorted because of moisture or something on the PCB.

Spelling mistakes are not intentional, I only seem to see them some time after I've posted

-

15-09-2014 #8

I think it is HY02D223B.

The wires seem to be ok. I have nice Igus cables.

Could you recommend a decent VFD? After this incident I do not want to deal with Chinese stuff any more.

I have only 230V single phase. I have one fuse in the CNC electronics enclosure and one in the workshop general fuse panel.

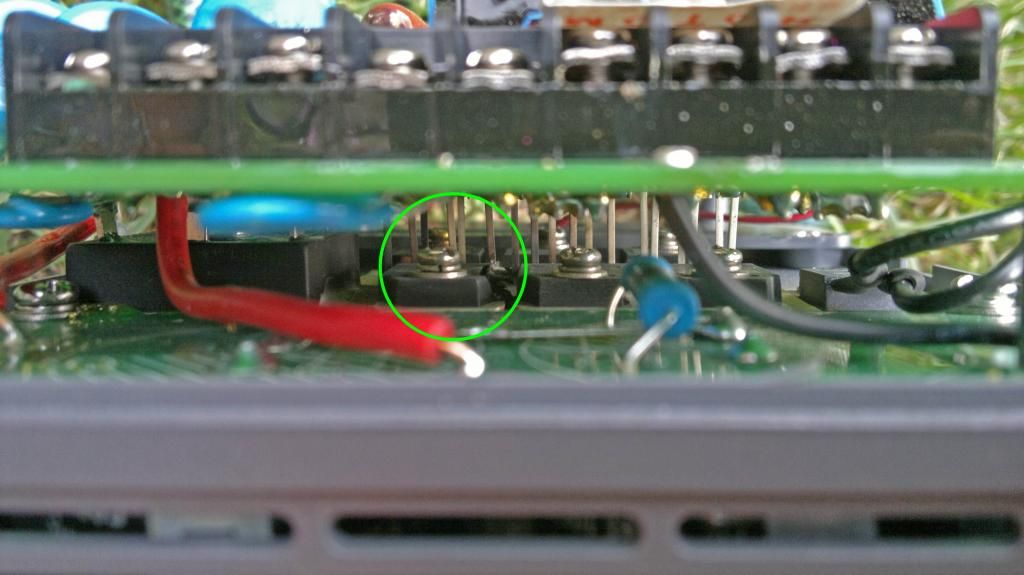

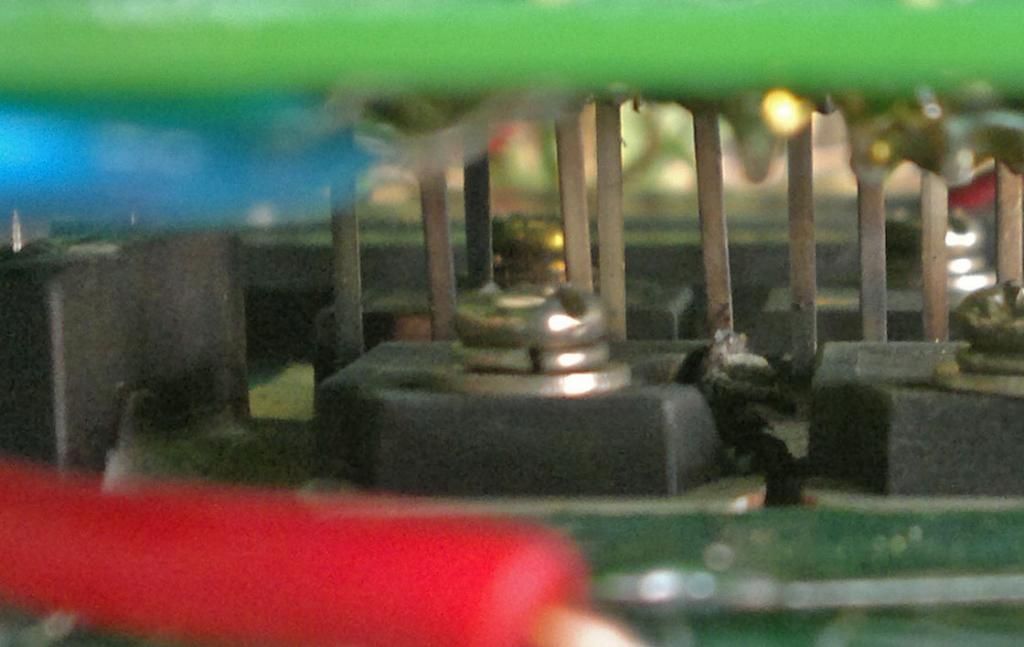

The circled thing exploded violently. I cannot read the part number on it.

Thank you allLast edited by paulus.v; 15-09-2014 at 06:56 AM.

-

15-09-2014 #9

that "thing" is one of the output MOSFETs, there should be 6 in total, 2 per motor phase...

-

15-09-2014 #10

Looking at that I'd not be suprised to find that the optoisolator that drives the Mosfet's gate terminal will have been toasted too. I'd definitely be sending that straight back.

Cheers

Robin

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Chinese Spindles

By Ricardoco in forum Generic Chinese SpindlesReplies: 123Last Post: 05-12-2016, 12:16 AM -

NEW MEMBER: magic from Magic CAD/CAM

By Magic in forum New Member IntroductionsReplies: 8Last Post: 16-07-2013, 11:20 AM -

WANTED: Chinese 1.5kw spindle/vfd

By Philly in forum Items WantedReplies: 5Last Post: 10-02-2013, 11:44 AM -

Bit of a favour please, your magic on engraving !?

By totts in forum CAD & CAM SoftwareReplies: 7Last Post: 25-04-2012, 10:12 AM -

Chinese 1.5kw Spindles

By jcb121 in forum Generic Chinese SpindlesReplies: 12Last Post: 28-07-2011, 06:20 PM

Reply With Quote

Reply With Quote

Bookmarks