Hybrid View

-

09-10-2014 #1

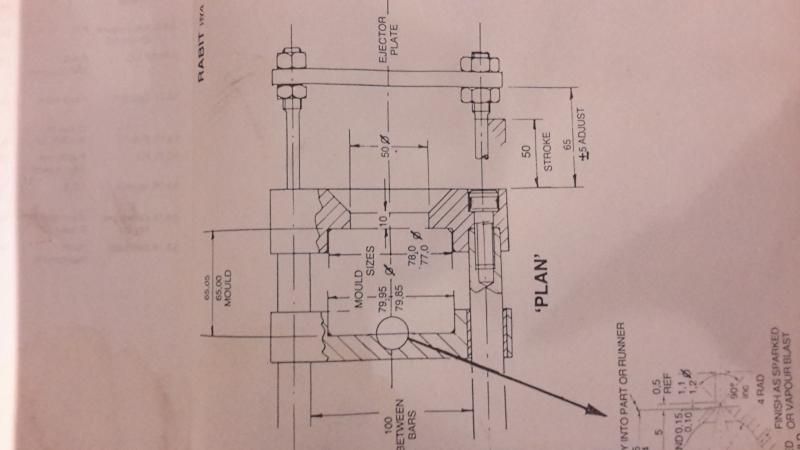

Robin - This is a diagram of the nozzle/injection entry on the rear of the mold. The 'small internal cone' I think is hot metal cone that keeps the plastic from setting in the entrance to the injector point. Is this what you call a plasticiser?

I think you are right that this is not so critical to get all the angles and rads just so. I think the only critical point would be the depth that the hot cone pokes into the mold specifically the 1.1mm diameter hole that feeds the mold cavitiy. If it goes in too far it will block the mold and if its too far away it might allow the plastic to set?CNC routing and prototyping services www.cncscotland.co.uk

ADD ME ON FACEBOOKS

ADD ME ON FACEBOOKS

-

09-10-2014 #2

If you can get an engraving bit with the 60 deg angle you should be able to do it.

If you go over to http://www.model-engineer.co.uk/ and look up "D" bits this will show you how to make one from silver steel, drill your hole go in with the "D" bit to the required depth then tickle the hole with the engraving bit.

Good Luck

Mike

-

09-10-2014 #3

Thanks Mike,

Most center drills are 60 degree I think? Shame they have a that little drill point on the end (Maybe I could turn that down to continue the 60 degree shape?). Anyway I should be able to pickup a 60 chamfer or engraving tool.

So I think the plan would be.

1. Drill 1mm hole straight through. (Hopefully easy in alu?)

2. Use 60 degree tool to hog out material and form 60 shape.

3. Use a small 90 degree tool widen the 1mm hole entrance

4. Use 4mm rad ballnose to blend the 60 and 90 degree shapes by eye?CNC routing and prototyping services www.cncscotland.co.uk

ADD ME ON FACEBOOKS

ADD ME ON FACEBOOKS

-

09-10-2014 #4

Yes first op is drill the hole, you then want to remove the bulk of the material as you would probably break the engraving tool if you tried to open it out with that, also just checked the angles the 60 deg is refering to the larger opening that blends with the 45deg, the taper that opens out the hole has an included angle of 30 deg so you need an engraving tool that size, so remove the bulk machining the 45deg taper then go in with your 8mm dia ball nose cutter then just blend out with the 60 deg taper and tickle out the 30 deg taper with the engraving tool. FYI a "D" bit is just a form tool you basically turn the required profile with the drive dia slightly offset then machine away the profile leaving it flat topped to the centre line of the driving diameter, this gives the profile a "D" shape and a cutting clearance.

Regards

Mike

Reg

-

09-10-2014 #5I think the 30 degree taper is not part of the mold but instead part of the machine that injects the plastic. My thoughts are this is a heated tip and the plastic will flow around this?the taper that opens out the hole has an included angle of 30 deg so you need an engraving tool that size,CNC routing and prototyping services www.cncscotland.co.uk

ADD ME ON FACEBOOKS

ADD ME ON FACEBOOKS

-

09-10-2014 #6

That makes it relatively easy to make then, carry on number one.

Mike

-

09-10-2014 #7

I'm still not understanding what I am looking at.

The plasticiser is the bit that converts granular plastic to melt. This has to connect to the mould, inject the melt, hold the pressure until something freezes, gates, sprue, whatever, disconnect from the mould and melt more granules.

Generally there are 3 ways in to a mould. On the mould parting line, through a sprue bushing, through heated runners where the melt never sets.

I thought that sprue bushing was usually a flat on flat seal with maybe a puff of cold air if stringing got too bad.

I thought I saw something like a countersunk screw head shaped cavity in your picture which would be fine and dandy if it was on the mould parting line because you wouldn't have to worry about getting it all out before the next shot.

-

09-10-2014 #8

Last edited by gavztheouch; 09-10-2014 at 09:02 PM.

CNC routing and prototyping services www.cncscotland.co.uk

ADD ME ON FACEBOOKS

ADD ME ON FACEBOOKS

-

09-10-2014 #9

So you have two tie bars 4" apart. The platens have 3" indents presumably to locate the mould halves. The moving platen (top) has a 2" hole through which the ejector pins pass.

Can we assume the fixed platen (bottom) has a similar hole, which isn't shown, and the nozzle comes up from below, the drawing Y axis, through that hole. It does not come in from above, the drawing Z axis, to hit the parting line.

-

09-10-2014 #10

Yes the nozzle does come up from below in the diagram, but I have it round the wrong way, it needs to be rotated 90 degrees. This is a horizontal machine.

Last edited by gavztheouch; 10-10-2014 at 09:20 AM.

CNC routing and prototyping services www.cncscotland.co.uk

ADD ME ON FACEBOOKS

ADD ME ON FACEBOOKS

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Plastic injection mold making forum?

By gavztheouch in forum Moulding MachinesReplies: 26Last Post: 13-10-2022, 11:31 AM -

New toy - Arburg injection moulder

By Robin Hewitt in forum Moulding MachinesReplies: 13Last Post: 26-10-2014, 11:59 PM -

RFQ: Any Injection Moulders on here, before I buy Chinese ?

By Bazzer in forum Projects, Jobs & RequestsReplies: 11Last Post: 18-05-2013, 11:25 AM -

DIY Injection moulding by JR Hartley.

By HankMcSpank in forum Moulding MachinesReplies: 26Last Post: 04-01-2013, 12:41 AM -

Proxxon MF70 for making injection molds

By forrest in forum Moulding MachinesReplies: 8Last Post: 11-04-2012, 11:30 PM

Reply With Quote

Reply With Quote

Bookmarks