-

28-12-2014 #1

Hi Fellas

As well as deeper 2D milling I will also be engraving small metal buckles. As Im not going deep if the work piece is not 100% spot on level then Ill get spots that are missed if its down at one end say.

What tips and tricks do you use for getting your work piece 100% level ?

My buckles are around 24x30mm and at the moment im dropping them into a pocket I machined from aluminium plate. Trouble is, just a tiny missed bit of swarf between the table and Jig or pocket and buckle can be enough to throw it off a smidgen.

I could skim over them before engraving but I pre 'grain' the top prior to engraving.

HHHmm, any thoughts ?

Thank you

Carl

-

28-12-2014 #2

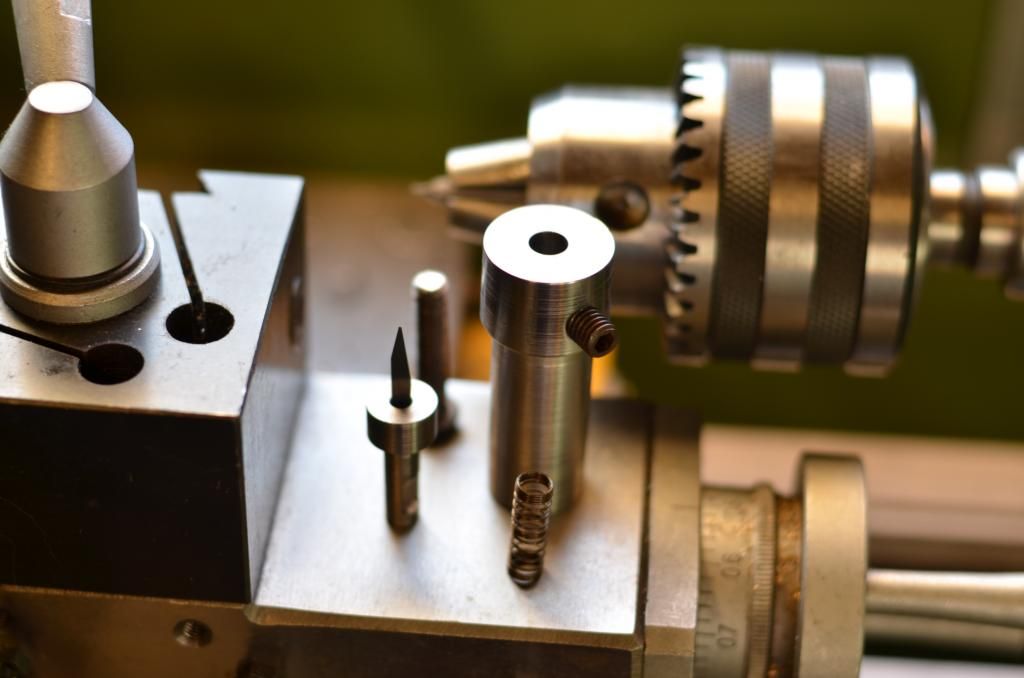

Spring loaded engraver bit is needed if surface isn't flat. Like this http://www.2linc.com/engraving.htm

-

29-12-2014 #3

-

29-12-2014 #4

Im a little confused at how this works, so whats stopping it from engraving too deep on the high spots? As gradually the spring pressure will engrave deeper? Or am i looking at this totally wrong?

-

29-12-2014 #5

It will engrave deeper at the high spots but not significantly so, not for me anyway :-)

Im not sure of the difference in hight from high to low spots on my plates Im engraving but its hardly anything, probably a nats chuff :-)

Mostly I get them dead flat but this seems to have solved it if they are off a smidg as I had no missed bits on this batch of buckles.

Im not sure how a commercially available one would work any different?

-

29-12-2014 #6

So when you set the z datum do you just set it a bit lower so it touches in the low spot, so are we saying that the spring acts as a damper in the high spots to stop the tip from chipping/breaking?

-

29-12-2014 #7

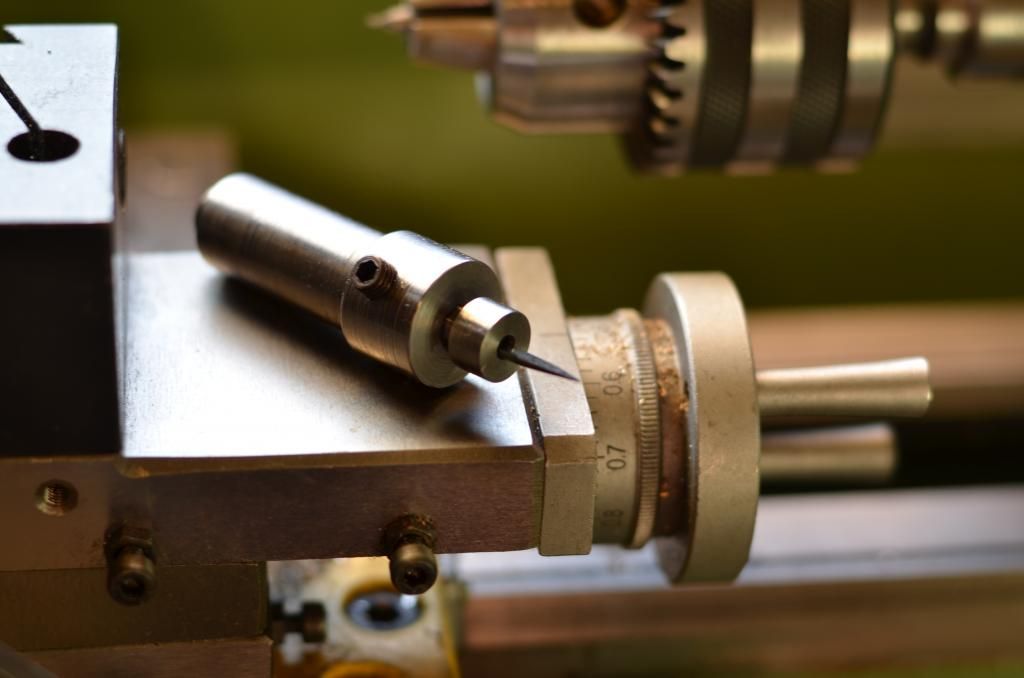

I set the Z offset of the tool exactly the same way as I would if a normal tool was in there. I then set the depth in the program as usual.

I was having tips break but with the spring taking up the initial impact it's been so far so good. I'm cutting stainless steel so it's a big ask for the tiny cutter, especially as I'm a noob and still learning. The high and low spots are littraly a nats chuff so with a solid tip and a shallow cut it was missing some.

Ive also used a diamond drag tip in it too and seems to work well too !

-

29-12-2014 #8

Yeh i can see how the drag engraver would work well, i had a variation of about .2mm so i may make one for the next time i have difficulty and see how it goes :) will pinch your idea haha

Cheers

-

30-12-2014 #9

-

30-12-2014 #10

Nice solution. How does that grub screw effect the balance of the spindle you must be spinning quite fast with that tiny cutter?

CNC routing and prototyping services www.cncscotland.co.uk

ADD ME ON FACEBOOKS

ADD ME ON FACEBOOKS

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

NEW MEMBER: New to CNC and need some tips for what to look for when buying a laser cnc

By veviben in forum New Member IntroductionsReplies: 2Last Post: 12-12-2014, 09:28 PM -

eBay: 300W 12V-48V DC High speed air cooled spindle motor for engraving milling

By Swarfing in forum Items On eBay UKReplies: 0Last Post: 16-06-2013, 01:33 PM -

Carbide Tips in Packs of 2

By APT in forum Manufacturer NewsReplies: 4Last Post: 28-01-2013, 11:19 AM -

Looking for tips on making 2.5 x 1.25 mtr table

By psiron in forum Gantry/Router Machines & BuildingReplies: 9Last Post: 14-06-2010, 08:09 PM -

Bridgeport Tips & Advice

By Philmollatt in forum Milling Machines, Builds & ConversionsReplies: 2Last Post: 01-10-2009, 06:34 PM

Reply With Quote

Reply With Quote

Bookmarks