Thread: Vacuum table Setup Advice

-

10-09-2015 #41

I would use the compressor setup to resolve all table, mat and fixture issues. Once i know that all functions and what exactly i need i would buy then the proper sized vacuum pump.

Jumping to buy the first vacuum pump seen is not a good idea. From what i see from the picture you are again on the wrong path.

You need a 2 stage low volume high pressure vacuum pump / but enough volume/ , no high volume low pressure vacuum pump. These are not the proper technical words may be , just to have an idea what i am talking about.

This is exactly the vacuum pump my friend bought from ebay. he is using it for a vacuum chamber. I am thinking of buying one also. It seems to me its up to the task as i have seen it in real life. Its a sucker. 7cfm.

Check all specifications again including electrical, ask the vacuum table dealer or manufacturer if its ok and buy that sucker. It will be extremely unacceptable new, just check price :-)

-

10-09-2015 #42

-

10-09-2015 #43

Just to put my twopenorth in. I personally think that if you are cutting small parts in ally, don't bother with trying to use vacuum without some other form of clamping device. Use clamps, jigs, fixtures or whatever, but I think you will waste a lot of time and money with vacuum alone. I also do not believe that you will get away using only a single phase pump. If you are cuttig small parts from a large sheet area, it may work, really vacuum hold down is fsr better suited to timber/board type products. Anyway, good luck, but don't wastew too much time, effort or money. G.

-

10-09-2015 #44

-

10-09-2015 #45

How is 250mm by 150mm small?

-

10-09-2015 #46

-

10-09-2015 #47

-

10-09-2015 #48

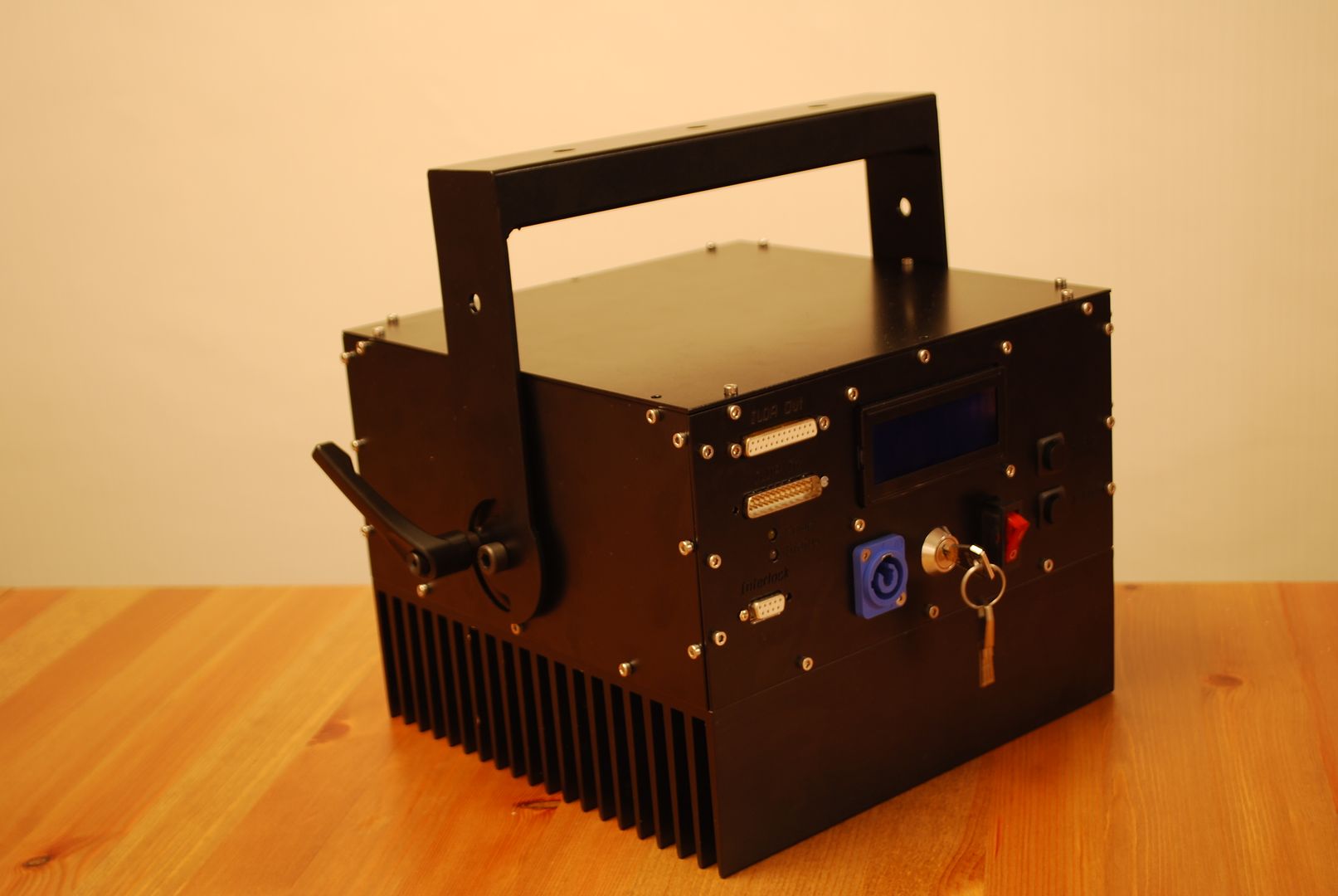

no word of a lie exactly this

I machined this case in separate panels, it took forever. so I want to machine these panels but on a vacuum table

-

10-09-2015 #49

Not sure why that would take for ever and certainly doesn't need a vacuum table. Those panels would take minutes using conventional hold down methods.!

Couple of intial clamps until few holes drilled then screw it down and carry on. Simplizzzz

-

10-09-2015 #50

yeah so square up on the table using a test dial.

clamp

drill some holes

remove and fix down to a jig

put back in mill and re-square using test dial

machine the rest.

or put straight onto a vacuum table and do the whole thing in one go

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

I want a vacuum table!

By Tenson in forum Machine DiscussionReplies: 44Last Post: 08-01-2014, 07:40 PM -

Vacuum Table Advice

By Minium in forum Milling Machines, Builds & ConversionsReplies: 13Last Post: 13-11-2012, 09:52 AM -

Custom Vacuum Table 'Hold Down' System - piping/valve advice

By FlightCaseCo in forum Machine DiscussionReplies: 4Last Post: 16-01-2012, 06:56 PM -

Much advice needed for an 8' x 4' cnc router project / and vacuum table

By FlightCaseCo in forum General DiscussionReplies: 1Last Post: 01-01-2012, 12:34 AM -

DIY Vacuum Table

By templecorran in forum Machine DiscussionReplies: 18Last Post: 10-11-2010, 12:11 AM

Reply With Quote

Reply With Quote

Bookmarks