Hybrid View

-

07-02-2016 #1

correct, 20mm or less would be fine.

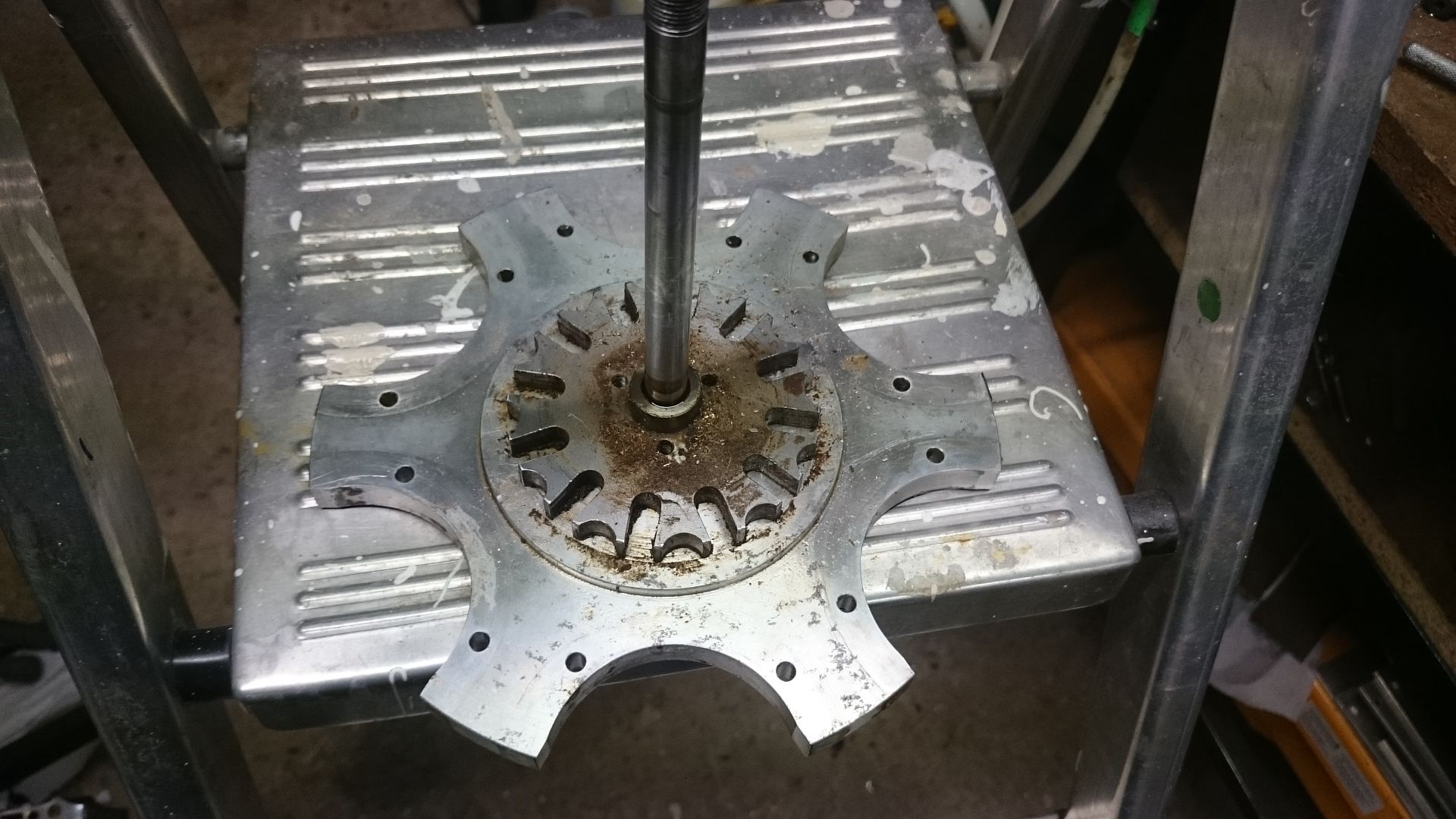

heres another photos to explain a bit more

you have the long steel rod with 3 holes which slides into the ally disk which holds the tools, then the cog goes on top of the ally disk. the dia of that steel rod is not changeable and will be used on the new setup. that steel rod fits perfectly into the rest of the arms and bearings etc...

-

07-02-2016 #2

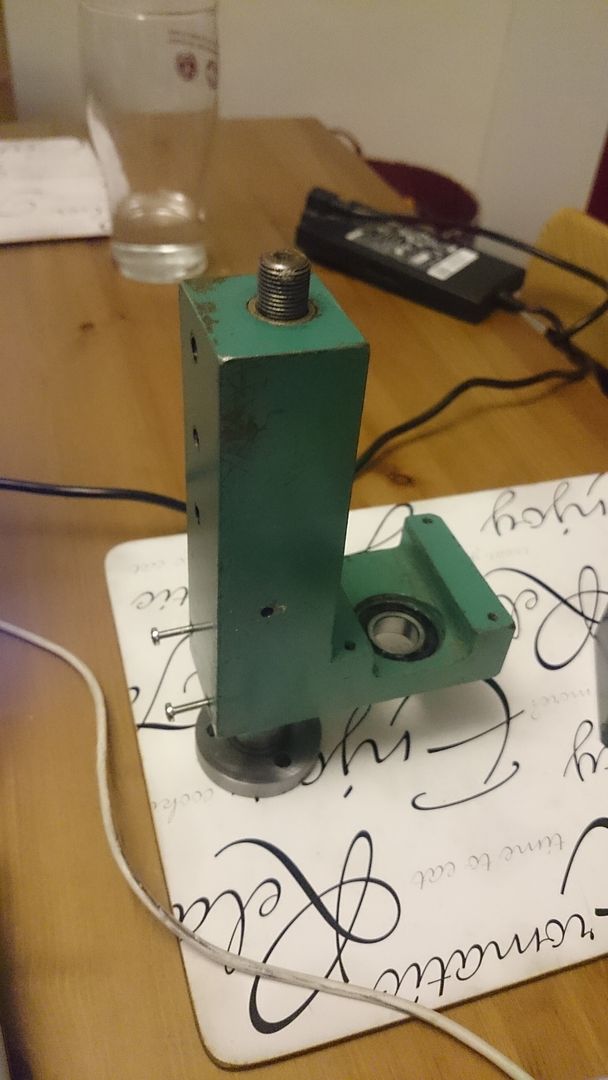

current setup

so these are the bits that will remain that I have to work with

green cast iron arm and steel rod insert which the new ally disk will mount to

-

08-02-2016 #3

just been speaking to a friend with a lathe whos going to make me a little shaft extender to go on the nema so I can attached a pulley to the other end to solve the height issue.

so I just need some recommendations on two toothed pulleys with matching belt to fit a centre distance of 47.5mm

-

08-02-2016 #4

-

08-02-2016 #5

So then you are stuck with min size pulley HTD 5m 20 teeth having in mind 20mm bore:

Then we go to the belt calculator, play a little with it and find that voilaa, if i am not wrong you have a hit.

we search the web for the 180mm HTD 5m belt and find that indeed there is one existing in this size:

So more or less problem solved. Pulleys from belting online, contact them if they have the belt if not search and buy. its a good idea to pay them to bore the pulley as they do it well and wall thickness will be alright at 3mm as per drawing above.

So problem solved? Right? if you want to mill them or to do them i could pass you a dxf drawing of any tooth count you need for HTD5 pulleysLast edited by Boyan Silyavski; 08-02-2016 at 12:51 AM.

-

08-02-2016 #6

So are thinking to do away with the Geneva wheel.? If so then I'd re-think it because with such large diameter disc and lot of weight then stepper may struggle to hold position good enough, esp with higher rotating speed with more weight. You'll certainly need fair ratio on it.!

Last edited by JAZZCNC; 08-02-2016 at 01:32 AM.

-

08-02-2016 #7

-

08-02-2016 #8So then you are stuck with min size pulley HTD 5m 20 teeth having in mind 20mm bore:

Then we go to the belt calculator, play a little with it and find that voilaa, if i am not wrong you have a hit.

we search the web for the 180mm HTD 5m belt and find that indeed there is one existing in this size:

So more or less problem solved. Pulleys from belting online, contact them if they have the belt if not search and buy. its a good idea to pay them to bore the pulley as they do it well and wall thickness will be alright at 3mm as per drawing above.

So problem solved? Right? if you want to mill them or to do them i could pass you a dxf drawing of any tooth count you need for HTD5 pulleys

that is perfect, thank you very much.not sure I understand it all but I will contact them with this detail and buy a bits.many many thanksLast edited by andy_con; 08-02-2016 at 01:47 PM.

-

08-02-2016 #9So are thinking to do away with the Geneva wheel.? If so then I'd re-think it because with such large diameter disc and lot of weight then stepper may struggle to hold position good enough, esp with higher rotating speed with more weight. You'll certainly need fair ratio on it.!

yes I want rid of the Geneva wheel.the current disc is mounted via bearings and once in bits the ally disk that holds the tools is very free flowing in the green cast iron arm.I don't want it to run at high speed, but a bit fast then the current setup which is painfully slow. ill give it a go and see how it works, if it becomes a problem ill have to redesignLast edited by andy_con; 08-02-2016 at 01:48 PM.

-

08-02-2016 #10

Yes I know that but it's needs a High Ratio and decent sized stepper to handle the inertia of large diamter wheel fully loaded with tools and they do struggle if run fast resulting in overshooting. Which actually slows tool changing or If toolholder isn't perfectly lined up they rub and wear spindle/Pullstud resulting in dropped tools.!!

Geneva while still needs gearbox or ratio it does index perfctly and is more reliable. That's why they are used in ATC.!!Last edited by JAZZCNC; 08-02-2016 at 04:03 PM.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Hewing hall millgrav

By cncezee in forum Milling Machines, Builds & ConversionsReplies: 26Last Post: 19-12-2020, 07:16 AM -

EXPERIENCE: CorkCNC custom part

By MarkLeeds2K5 in forum Trading Experience & FeedbackReplies: 0Last Post: 28-01-2016, 06:43 PM -

RFQ: Custom CNC work - Just wondering how much...

By Mustang80 in forum Projects, Jobs & RequestsReplies: 0Last Post: 02-10-2011, 07:53 PM -

pulley ratios on 3 pulley axis

By Swarfing in forum Belt Drive, Pulleys & TimingReplies: 35Last Post: 21-07-2011, 12:43 AM -

Custom power DC supply

By M250cnc in forum Electronic Project BuildingReplies: 11Last Post: 22-11-2010, 09:48 PM

Reply With Quote

Reply With Quote

Bookmarks