Thread: Thor, or should that be Zeus?

Hybrid View

-

13-04-2016 #1

Small update. Ive decided to get longer rails for Z, 700mm, this will arrive in the next two weeks. I am starting to look at building the moulds for the base and gantry systems. I have also ordered the epoxy as well as putty / liquid for levelling that I need.

Hope to provide some updates again soon on this build.

-

24-04-2016 #2

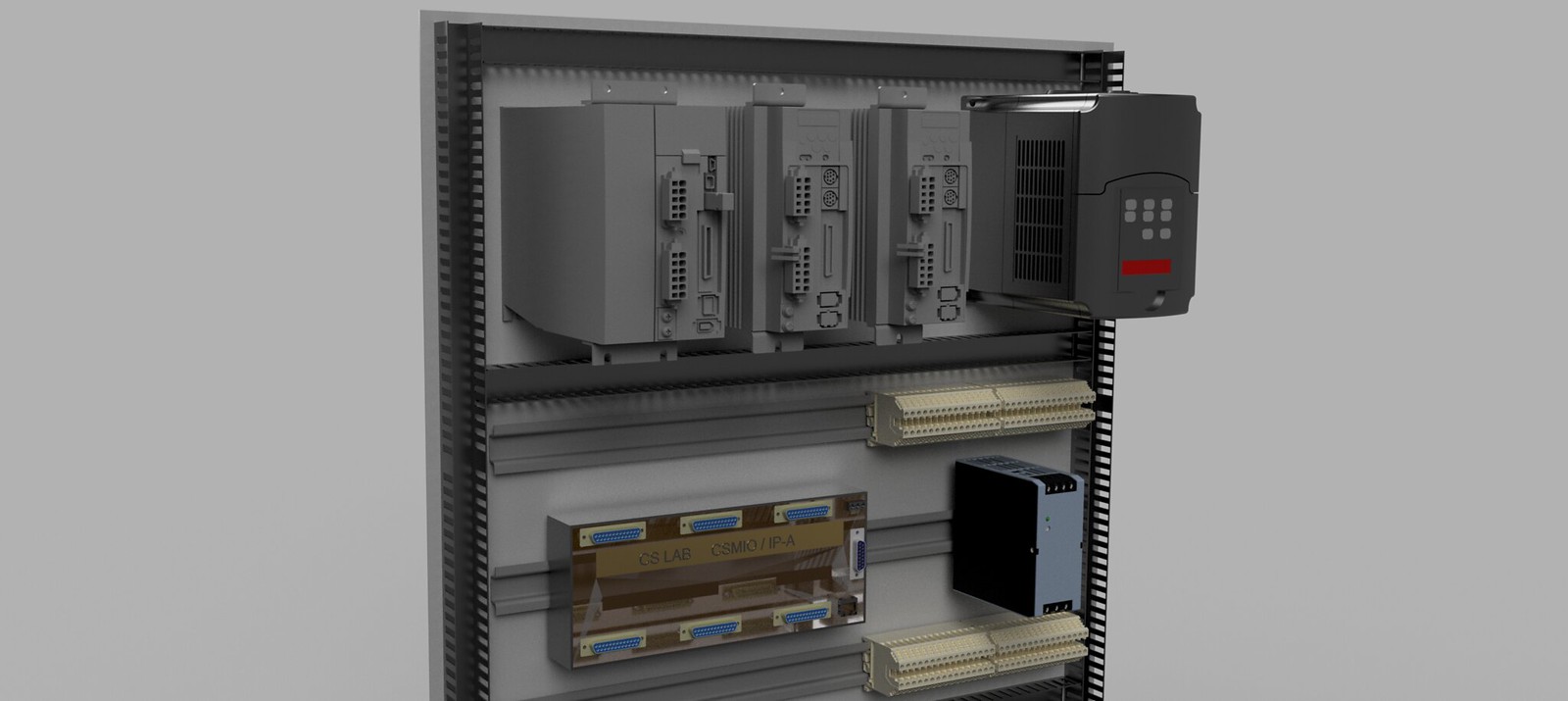

Did some turning to make some spacers for the ballscrews. Also started with some layout ideas for the electronics.

-

25-04-2016 #3

-

08-01-2017 #4

-

09-01-2017 #5

-

09-01-2017 #6

Agreed. Im trying to balance spending money / finding a new role and a bunch of other things at the moment.

Any suggestions on sourcing BT30 spindle / motors setups? Ive heard that the POSA BT30 from the far east is one of the better ones. http://www.posa-spindle.com/en/product-53-30

I also have the option on the Skyfire setup although there is a lot of bad press about them missing shipment dates and going off grid once you pay.

Any other suggestions? Anything locally that is worth a look. Ideally Id want at least 12K RPM if possible.

-

09-01-2017 #7

If i were you, i would evaluate what exactly i will be doing, as first jobs and jobs that i make money from. Then decide what spindle to put there, according to the jobs i will be doing.

If you are going to do engraving, aluminum and so on, then 24krpm will definitely be much better. Especially if you are going to use bits 6mm or smaller than that. Thats why i opted for 3kw spindle on my machine and i am very happy. But if you are going to do mild steel mainly, then you need the BT30 or other.

All in one is not a very good option. In fact your machine best will be fit with 3kw 24k RPM and BT30 or similar., both at the same time. I know, $$$, other wise i would have fitted High speed tool change spindle BT30 on mine.

Follow the $$ priorities and you will not do wrong / the making $$, not spending $$ /

/

-

09-01-2017 #8

In this, I was not specifically referring to making money from the machine to be it's purpose, was referring to my own day job but agreed, I need to decide what the machine will be used for.

So are you saying doing both may be a good option or not? Sorry, not sure if the 'not' in your sentence is correct or not.

Ideally it would be good to have something versatile. If I can engineer a solution when you can almost do a 'multi head' setup. Heck, even look at some form of grinding attachment, potentially with a very high geared 2nd Z setup that can hang off the side or front of this Z Axis.

-

24-05-2017 #9

And me, just not on here that much at the moment...

Sent from my HUAWEI VNS-L31 using Tapatalk

-

25-05-2017 #10

I'm also watching.

Not had much time to post much, as I'm gearing up for a few weeks of work chaos. Normal service should resume sometime next month.Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

Thread Information

Users Browsing this Thread

There are currently 3 users browsing this thread. (0 members and 3 guests)

Reply With Quote

Reply With Quote

Bookmarks