Thread: Thor, or should that be Zeus?

-

29-02-2016 #1

So previously, I built a CNC router that was, frankly, a waste of money. JazzCNC kindly referred to it as 'made from spaghetti'.

Since that time, I have bought and retrofitted my Denford VMC which I still have but will sell once Thor, or Zeus is created. I want to have a machine that can move quick, cut Alu with ease and potential a bit more too. I dont generally work with steel but Id like the option to cut some at times.

Ive been itching to do a new build for a while and pulled the trigger recently on some parts. I kinda started a thread looking at some design ideas a few months ago however I wasnt sure that the design I was showing would work. I found some bits online and am now designing around some parts that I have.

If there is one thing to achieve, is a machine a bit more rigid than spaghetti. I am hoping that when you look at the selected parts, this may be achievable.

Let's discuss design first.

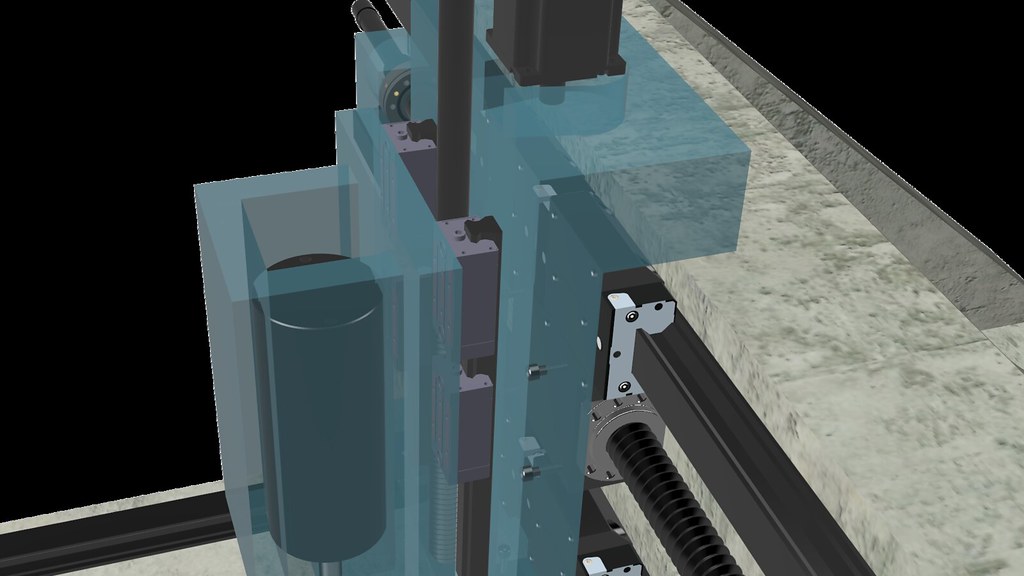

Thor, fixed gantry design, the base and gantry designs are not complete, there is a lot of optimisation that can be done. I wanted to get an idea of machine size, weight and design options with the specific rails and ballscrews I have. I have also spent a lot of time reading different whitepapers on machine design and whilst I certainly dont know a lot, I understand a lot more about some of the design criteria, materials and rigidity.

Thor is a fixed gantry system. I originally wanted to do moving gantry (like the Datron machines) however I was dissuaded on this on the basis of getting good rigidity is difficult and I dont want to run two ballscrews / motors for Y. The availability of the bits I bought have also contributed to this.

Subsequent to this design, a number of concerns came up. Some of them are around how to make the structure and get the surfaces flat. I intend using either UHPC or some variant or some form of Epoxy Granite or similar.

I then spent some time over the weekend going back to a fixed head design. I watched many videos where a lot of modern machines use this tried and tested method and the design below, suitably called Zeus, was born.

Whilst I was coming up with the design, I really struggled with getting the Y table size larger than 65% of what the fixed gantry offers. The 'overhang' of the Z Axis is also concerning however I kept at it.

I then spoke to the person that has sold me all the mechanical bits (my pimp) and his advice is to go with the fixed gantry design. We discussed this at length and currently, my plan is to build Thor (top design).

So, parts.

X Rails - Bosch Rexroth 45mm rails, 1180mm long using high preload roller bearing carts.

Y Rails - as above.

Z Rails - INA 25mm rails, 346mm long (I'm trying to source 500mm rails) with roller bearing carts.

Ballscrews, well, I have a selection. For X and Y I have 6 leadscrews, all 40mm with dual preloaded ballnuts and different pitch options from 10 to 20 mm.

For Z, I have some Eisenmann screws, 32mm, 5mm Lead, dual preload ballnut.

Motorwise, I may have jumped the gun a bit but I am hoping that with all the different options of screws (all use 3080 mounting bearing) that Ill find something that works well in terms of pulley ratios.

I have gone for Panasonic Servos, A4 range. 1.5KW for Y, 750W for X and Z. All of this will be controlled with the CS Labs IP-A unit.

All in all, I am looking forward to this build. I'd love to be testing already but still very far from that.

No more spaghetti and aiming to get speeds of around 20m/min with acc rates of 5m^2.

-

29-02-2016 #2

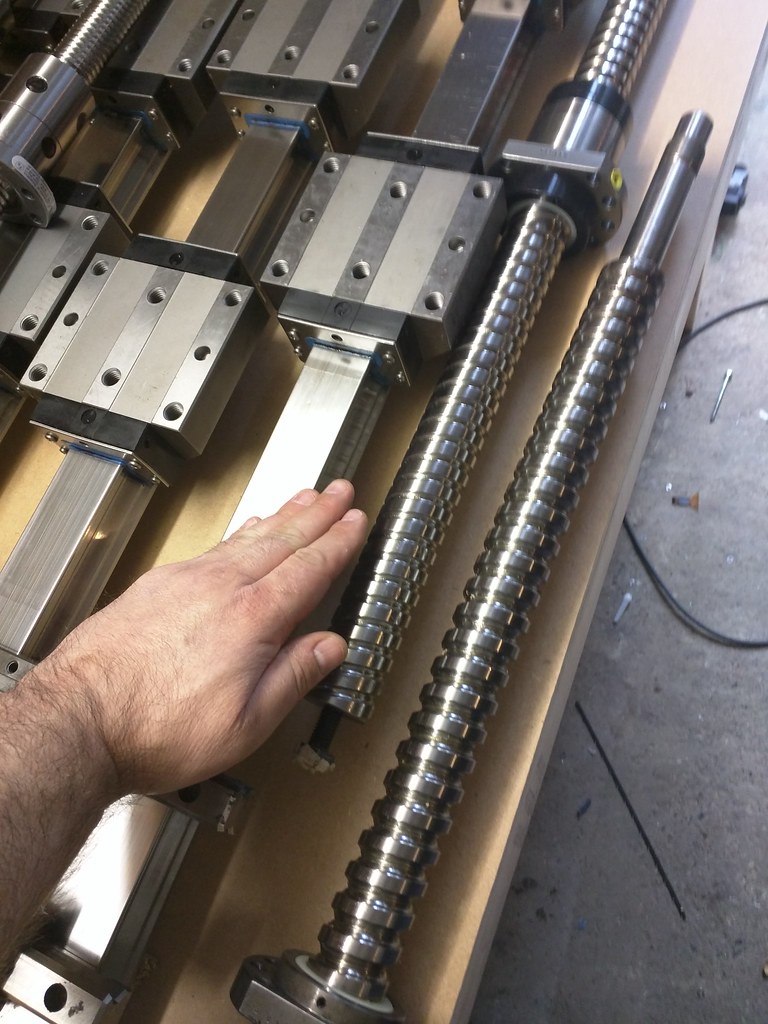

I forgot to add pics of the hardware.

Below, my hand for scale / size. I can now understand why the shipment was 200 kg :-)

-

The Following User Says Thank You to Chaz For This Useful Post:

-

29-02-2016 #3

Omg! The names seems appropriate, or maybe tankbuster! ;) will follow this!

-

01-03-2016 #4

Great! Now even i am surprised. I will be following with great interest. OMG

Charl, now i see what your are up to. Would you like to see the drawing of my Z on mine big machine? It would be very appropriate if you decide on using 3kw-5kw high speed spindle. The overhang i achieved is ridiculously low. Unfortunately still not in proper cad but Sketchup. But you could draw some ideas from it.

Or you will go the BT30 way?Last edited by Boyan Silyavski; 01-03-2016 at 03:44 AM.

-

01-03-2016 #5

Hi, yes, please. Any inspiration, ideas, comments, feedback appreciated. Feel free to email to me, Ill convert it.

At the moment, I am looking at options for spindles. Current view is to either have 4KW Chinese spindle or perhaps something more expensive (if budget allows) something better.

Id love to go to BT30 but not designing around this at present.

-

01-03-2016 #6

Theoretically the bearing blocks should be bolted to the gantry and the rails to the bottom of the bed. If you put the blocks on the bed you introduce unnecessary overhangs and add a lot of metal supporting rails that does nothing. It should be more A frame and less triangular. OTOH, what do I know? -freaking smileys don't work-

-

01-03-2016 #7

-

01-03-2016 #8

Wow Chaz - excellent thread. Great to see someone putting a bit of thought in and going for it!

I would lean towards Thor, the top design, although both would do well.

In my new mk4 design I had to go with moving gantry because I still need to cut large wooden sheets, but with your brief these designs are excellent.

If the granite epoxy is too difficult to make/cast then it looks like it could be done with say 150x50mm sections all welded together. Then backfilled with epoxy granite. Weld on some flat 10mm bar where each rail will go, get it skimmed flat, and there you are.

For the spindle I wonder if you could have a bolt-on high speed spindle for aluminium (router mode), then bolt on a heavily geared down spindle for steel (mill mode). Or have both in place so you can choose.

Good luck with however you choose to develop this - watching with interest.

-

01-03-2016 #9

Thanks. We have discussed a dual spindle setup. I might want to stick a grinding spindle in there too somehow :-)

I'm looking at rail options for the Z at present, I have some other options to consider although already spent a small fortune on the parts thus far. I will have leftovers, will likely be put into a DIY CNC Lathe.

-

01-03-2016 #10

Thread Information

Users Browsing this Thread

There are currently 3 users browsing this thread. (0 members and 3 guests)

Reply With Quote

Reply With Quote

Bookmarks