Thread: Thor, or should that be Zeus?

-

12-08-2017 #431

What probe did you buy?

One thing you'll need to check, is what voltage/current the probe is designed to work with. I made up a small interface board for my probe, so it was only switching the designed 5V, so I could use it to switch a 24V opto. Details can be found in this post over on the mach forum - http://www.machsupport.com/forum/ind...html#msg195436Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

12-08-2017 #432

Two of these, almost a year ago, lol.

https://www.machsupport.com/forum/in...ic,5004.0.html

-

29-08-2017 #433

So Ive bit the bullet and bought a 'proper' probe. Its mechanical, not electrical and I want to make an arm for it like the Datron has that comes down, probes and I can then move it back in the 'up' position when not needed. Thinking to use some form of offsets to make this work.

How do I manage with an arm to rotate 180 degrees? Arduino Uno and servo? Id need a fairly strong servo me thinks ....

Thoughts?

-

29-08-2017 #434

Do you think it is possible to rotate about a hole/pin and get the repeatability ? How about sliding the arm up and down with a piece of spring steel to hold it against a ground edge? Could have a slot in the middle with a fixed dowel pin to give top and bottom end stops. Then add detents for top and bottom position. Manually move it up and down as required or drive it via a motor with a cam?

-

29-08-2017 #435

-

11-10-2017 #436

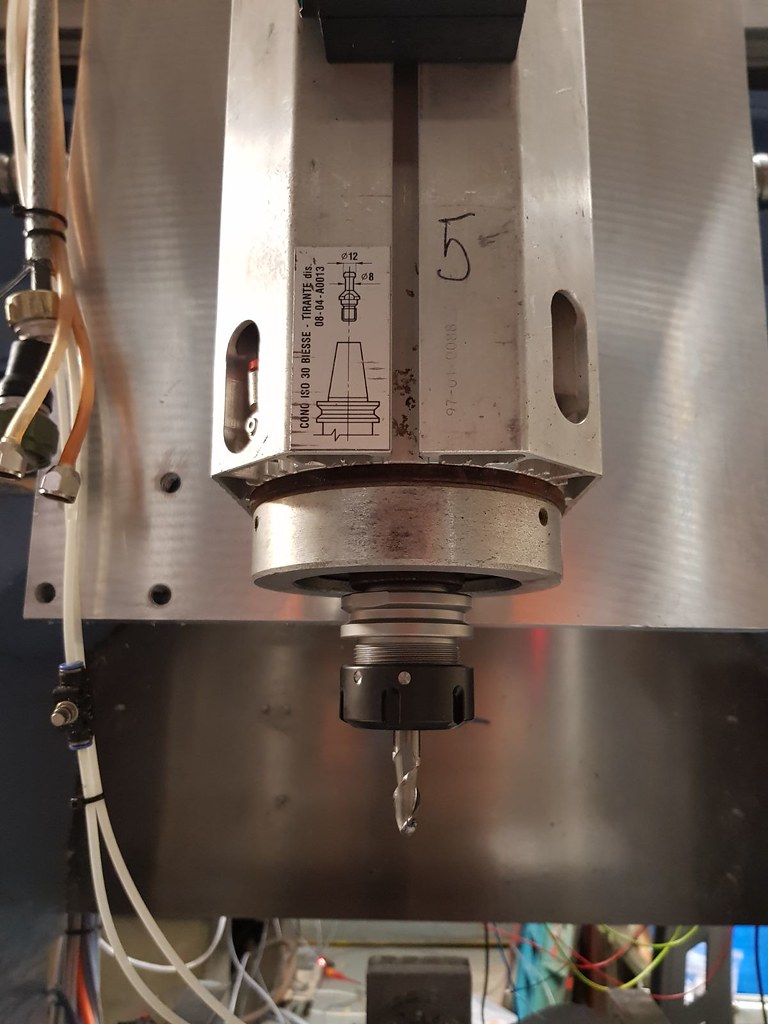

So Thor has had a bit of an upgrade / make over.

Spot the difference.

-

The Following User Says Thank You to Chaz For This Useful Post:

-

11-10-2017 #437

Go on Chaz give us a clue

On another note what is the max spindle speed and a link to it would be nice...Clive

The more you know, The better you know, How little you know

-

12-10-2017 #438

I know the answer but you told me lol having seen Thor though I could have spotted it anyway ;)

Congrats ;)http://www.mycncuk.com/threads/10880...60cm-work-area My first CNC build WIP 120cm*80cm

If you didn't buy it from China the company you bought it from did ;)

-

12-10-2017 #439

Its an HSD ES909. 6.8KW 24K RPM with ISO 30 tool holding. Small issue to actually power it but working on that. It runs happily off 220V, even though its a 380V unit. I cant get to the wiring to Delta the motor (these came as options for both voltages) so I'm hoping that I can run off 220V for now. It has two thermisotors which will trip if it gets too hot. I dont need to cut at 6 KW, even at 2KW im removing a fair bit of material and I now have an tool changer. Buying balanced ISO 30 holders is pricy but will build up a collection once I am happy that this works reliably.

-

The Following User Says Thank You to Chaz For This Useful Post:

-

16-10-2017 #440

A quick test cut. Looks like Ill be ordering more tool holders. Happy with the initial results. My Z is fairly heavy however (As predicted), might need to look at changing the gearing on both X and Z axis now.

-

The Following User Says Thank You to Chaz For This Useful Post:

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Reply With Quote

Reply With Quote

Bookmarks