Thread: Thor, or should that be Zeus?

Hybrid View

-

06-03-2016 #1

Exactly, even with manual WD squirt, it only needs applying every few inches or more, just enough to keep the cutter flutes wet i guess.

Whats the best thing to put in a mistless system though??

-

06-03-2016 #2

Just for fun, here's the safety data sheet

http://www.wd40.co.uk/Files/WD40%20M...07-2015_EN.pdf

Curiously drying out of the HT circuits when your car won't start is no longer one of it's uses.

-

07-03-2016 #3

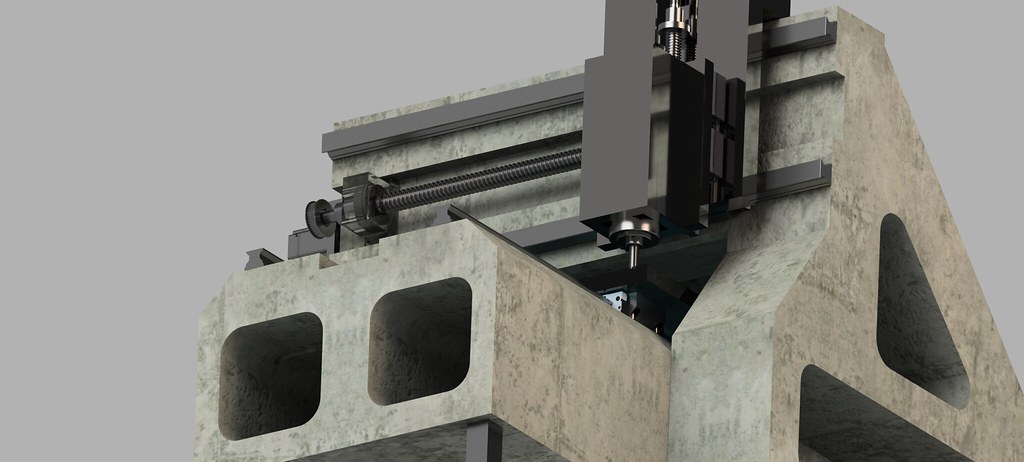

Have updated the design somewhat taking numerous feedback into consideration. Lots more to do before I start to make castings. I bought a lathe today, oldish Boxford Model A, should help with some round stuff I need for this build.

-

08-03-2016 #4

Guys,

Where can I buy cold rolled mild steel plate. I need pieces of metal of around 150mm x 150mm x 80mm (QTY 3). I dont really want to buy a full plate at 80mm size, struggling to find anywhere that will supply in small volume. Alu plate, easily source in this size, but not for mild steel.

Thanks

-

08-03-2016 #5

Just a quick question - Why so much mass in this design? Looking at the likes of production mills like Tormach etc, there is nowhere near as much mass in them and they are proven designs.

I like the ideas but over designing is surely as bad as under designing something ??

-

08-03-2016 #6

The idea is to allow for absorption of vibration etc. The hollows in the base structures improve strength and keep the weight bit more palatable. I need to check what the final weight estimate will be, I have had some issues with the files in Fusion, so redrawing some of the machine.

The idea here too is that this machine could be running a lot quicker (velocity and acceleration) than a Tormach. Considering the cost of a Tormach (ignore shipment / import duties, just the raw buy price), Thor should be a better machine.

The Tormach 1100 specs are below:-

110 IPM is 2800 mm/min. I am aiming for upwards of 10 000mm/min at least. The rails, ballscrews and motors that I am using cost more than the entire Tormach machine if I paid full new price (which I did not). This is before adding the controller, electronics, structure costs, spindle etc.Feed Rate: 110 IPM (X,Y)

90 IPM (Z)

-

08-03-2016 #7

Interesting, thanks.

I was only using Torch as an example really but those feed specs are interesting, any idea of the spindle HP rating? It's obviously designed for normal mill usage - bigger tooling, more cut depth, more radial cut depth so I guess 2800mm/min would be in that area.

I guess you will be running fairly high power motors to gain decent acceleration in small distances or it may never reach your high feeds??

Following your build with interest.

-

09-03-2016 #8

-

08-03-2016 #9

More mass=Less vibration=Perfect finish /while using perfect tools, perfect toolpaths, etc./

The big traps here being:

more mass=more mistakes during design=more money spend=same result or better with less mass

or

all perfect, but cheap tools, not adequately changing tools where needed, bad programming, so result is mediocre

Clearly if not for the sake of perfection itself, perfect finish, hard materials mostly or a production machine, there is no point going this way. I can not speak for him, but i made mine machine as it is OTT for 3 reasons:

-will machine mainly aluminum

-will machine long pieces like gantries of smaller machines, etc.

-the extra effort was not so expensive looking at the total of it and will pay off on first big job

-

08-03-2016 #10

Last edited by Davek0974; 08-03-2016 at 01:47 PM.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Reply With Quote

Reply With Quote

Bookmarks