Thread: Thor, or should that be Zeus?

-

13-04-2016 #61

Small update. Ive decided to get longer rails for Z, 700mm, this will arrive in the next two weeks. I am starting to look at building the moulds for the base and gantry systems. I have also ordered the epoxy as well as putty / liquid for levelling that I need.

Hope to provide some updates again soon on this build.

-

24-04-2016 #62

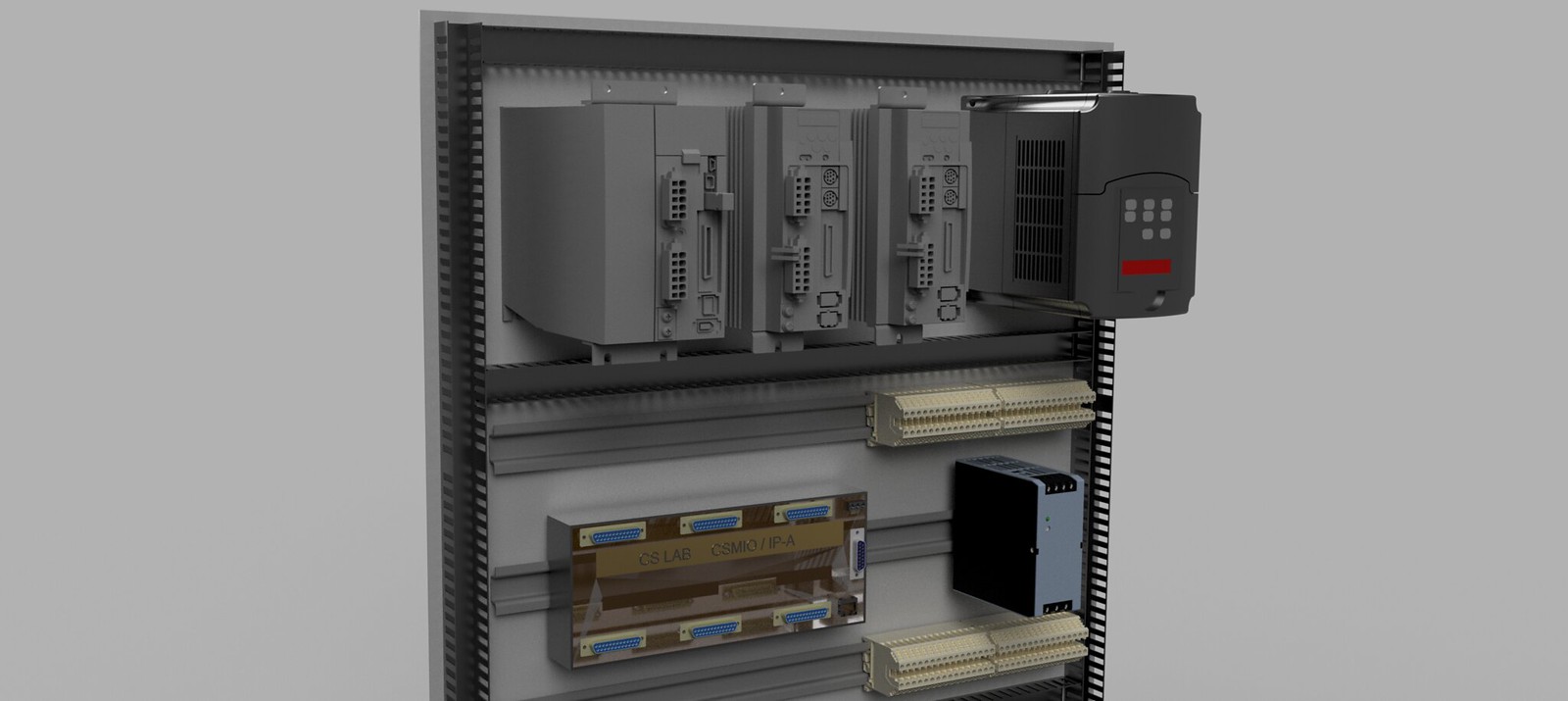

Did some turning to make some spacers for the ballscrews. Also started with some layout ideas for the electronics.

-

25-04-2016 #63

-

25-04-2016 #64

-

25-04-2016 #65

-

25-04-2016 #66

-

26-04-2016 #67

Are you following the manufacturer's guidelines for ventilation around those drives? ;-)

I've been working on the layout for my big mill cabinet, and I'll be opting for a bank of fans blowing air between the servo drives, as if I follow the dimensions in the manual, I'll not have enough room in the cabinet. And the cabinet is over 2' wide and 5' tall!Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

18-05-2016 #68

Looks like you've got a good project going here Chaz!

You seem responsive to feedback/criticism so I'll give you my two cents given I've been thinking of a very similar project.

First of all it really will be too 'solid', there isn't a need to make the frame so large with cavities to reduce the weight. Any cavity you introduce to the frame is just another process that needs to be worked out, why make it more complicated than it needs to be?

The A frame you've introduced will indeed be stronger but if you ever need to machine something that overhangs the table it may interfere with the frame. All commercial machines I've seen are vertical to make best use of the available space, if any extra strength is required it can be put at the back like your original design showed. It's a less 'efficient' use of material in terms of outright rigidity but is the best solution to the problem.

This is a pretty typical design, as you can see not much is allowed to get in the way of the workspace.

UHPC/EG may be weaker than steel and cast iron in every way, but it's also 1/3 of the density and less expensive. Use this to your advantage.

You appear to have the Y axis rail spacing as wide as possible, is there a good reason for this? If you bring them closer together you can create a more rigid table while at the same time reducing the width needed for the base of the frame. less width = more thickness = more rigid frame (for the same weight).

I think you really should look into getting a proper spindle, they really do make the biggest difference. Why cheap out on the thing that matters most? There are options available. I think a good question to ask would be, do you really need a high speed spindle? A 10,000 rpm milling spindle will be far more rigid and can make up for the slower speed by using bigger tools. Datron often use single flute tools, one of these at 30,000 rpm is similar to a 3 flute tool at 10,000 rpm.

I look forward to seeing how you progress, and remember there's more than one way to skin a cat. There's the right way, and there's the way people say it should be done.

Cheers,

Fenza

-

18-05-2016 #69

Thanks for the input. Ill try and answer where I can.

The plan is to revise the gantry to provide more clearance. Id prefer to over engineer than under, even if it costs a bit of extra time / effort.

In terms of the Y spacing, the guidance I was given was something like 4/6. So divide the width into 6 and space it about 2/3 each way. My understand is that wider = more resilient to any yaw movement.

In terms of spindle. Nothing is decided yet. The design is currently with a 4KW Chinese spindle but happy to change this. The reason I am looking at higher speed spindles is that I will primarily machine aluminium. Ive already taken a look at the spindles that Datron use and might go down this route.

The last comment is interesting. The right way and then what people suggest. I like the commentary and certainly makes me think about options. Of course not everyone will agree and some of what has been suggested I have either ruled out or accepted and changed accordingly. The person that I buy some of the hardware from has sent me images of what he works on for his day job. I cant share the images as they are proprietary and copyright but they show interesting machines, typically make from UHPC or EG on a massive scale (think of machines with beds in meters, not millimeters). The nice thing is that you can see how some of the designs took shape as well as some interesting structural methods of creating strength / rigidity. I dont have a mechanical background, so some of it looks 'odd' to my untrained eye but we are talking of machines that cost £500K upwards, its good to see what's out there and available. In some cases the structures are really 'basic'. In some cases, not.

-

19-05-2016 #70

2/3 of X travel? That sounds about right. Is your table not much larger than the travels of the mill? Not that it matters much just explains why the spacing looks so wide.

Maybe it'd be a good idea to show the guys here some pictures of the kind of work you want this machine to do? High speed spindle are great if the work can take advantage of it.

Cheers,

Fenza

Thread Information

Users Browsing this Thread

There are currently 2 users browsing this thread. (0 members and 2 guests)

Reply With Quote

Reply With Quote

Bookmarks