Thread: Thor, or should that be Zeus?

Threaded View

-

22-05-2016 #11

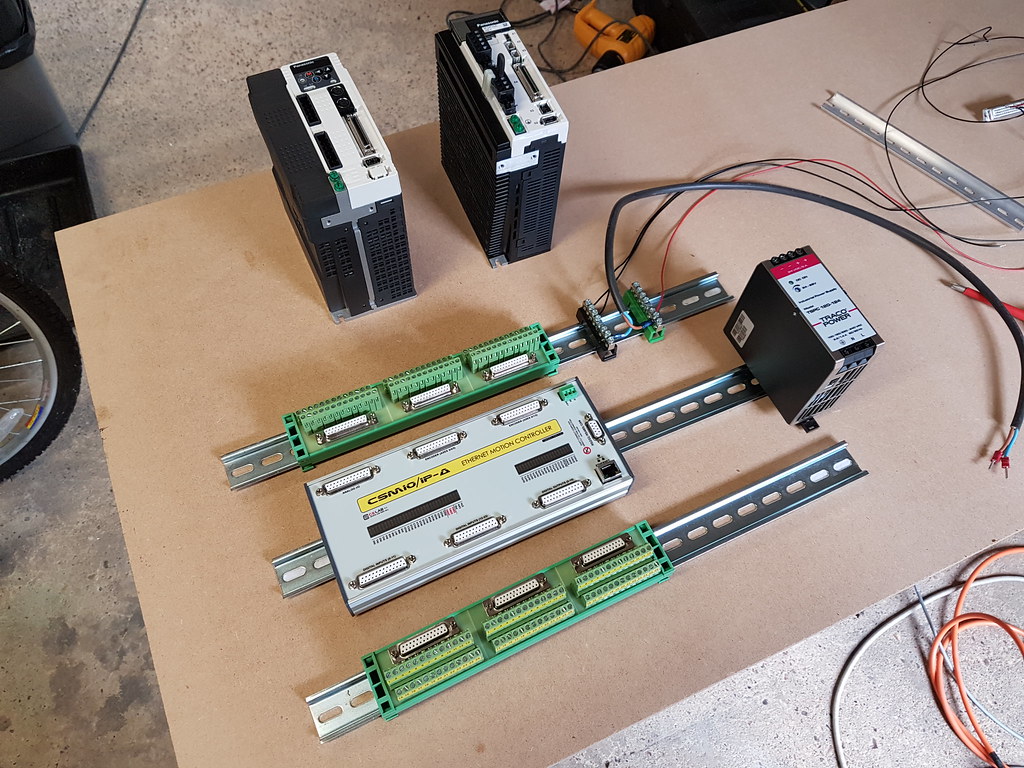

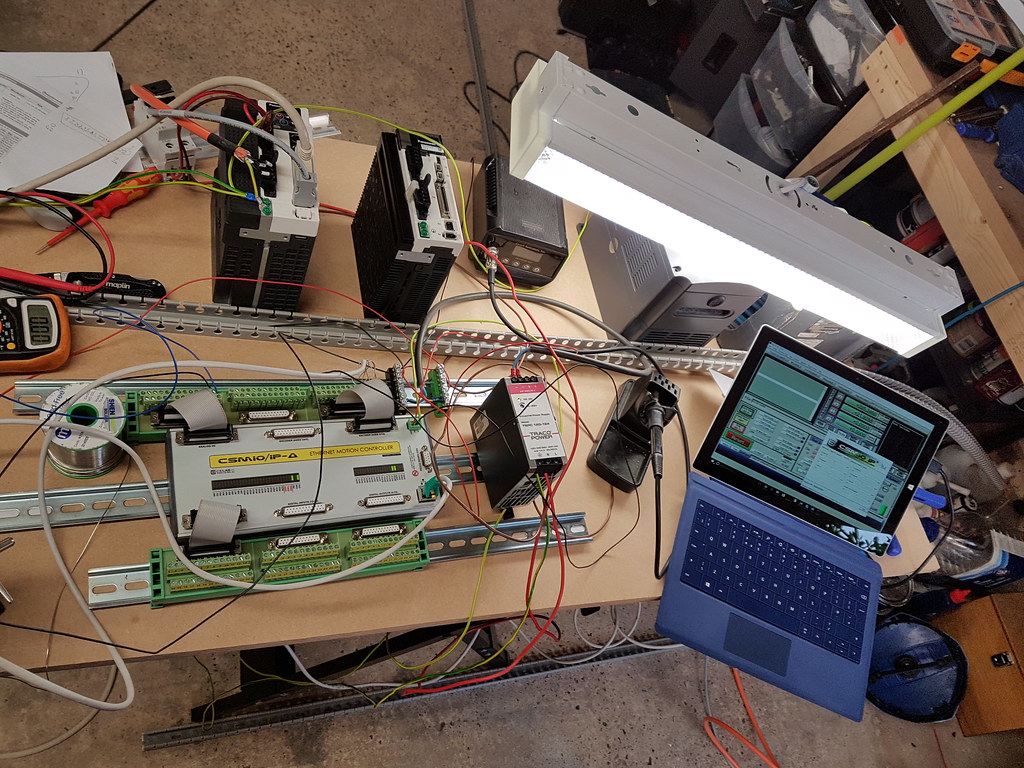

Started with the layout for the electrics. Ill mount onto a stainless plate most likely, this was just on MDF to get a feel for the size and get the basic X axis movement sorted.

A quick video, nothing is really calibrated but the motor seems happy to spin to 4000 rpm. Its a Panasonic 1.5KW motor and A4 drive powering it.

https://www.youtube.com/watch?v=Az4RkyfsDTE

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Reply With Quote

Reply With Quote

Bookmarks