Thread: Denford Microrouter V4

-

05-06-2016 #41

I just googled the stepper motor model number, and it threw up a few different datasheets/catalogues.

The catalogue for MAE stepper motors is http://www.probyte.fi/pdf/HY200-3424-0170.pdf

Which confirms the 3A/75V ratings.

However another datasheet put that exact same model at only 2.1A per phase.

I can't find any definitive figures for maximum temperature, but up to 80degC seems to be a common recommendation. If you are running the motors below their ratings, I wouldn't worry too much about it.

If you're not happy with them running that hot, try what Lucan suggests, and drop the current setting further.Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

06-06-2016 #42

Will drop the current one step

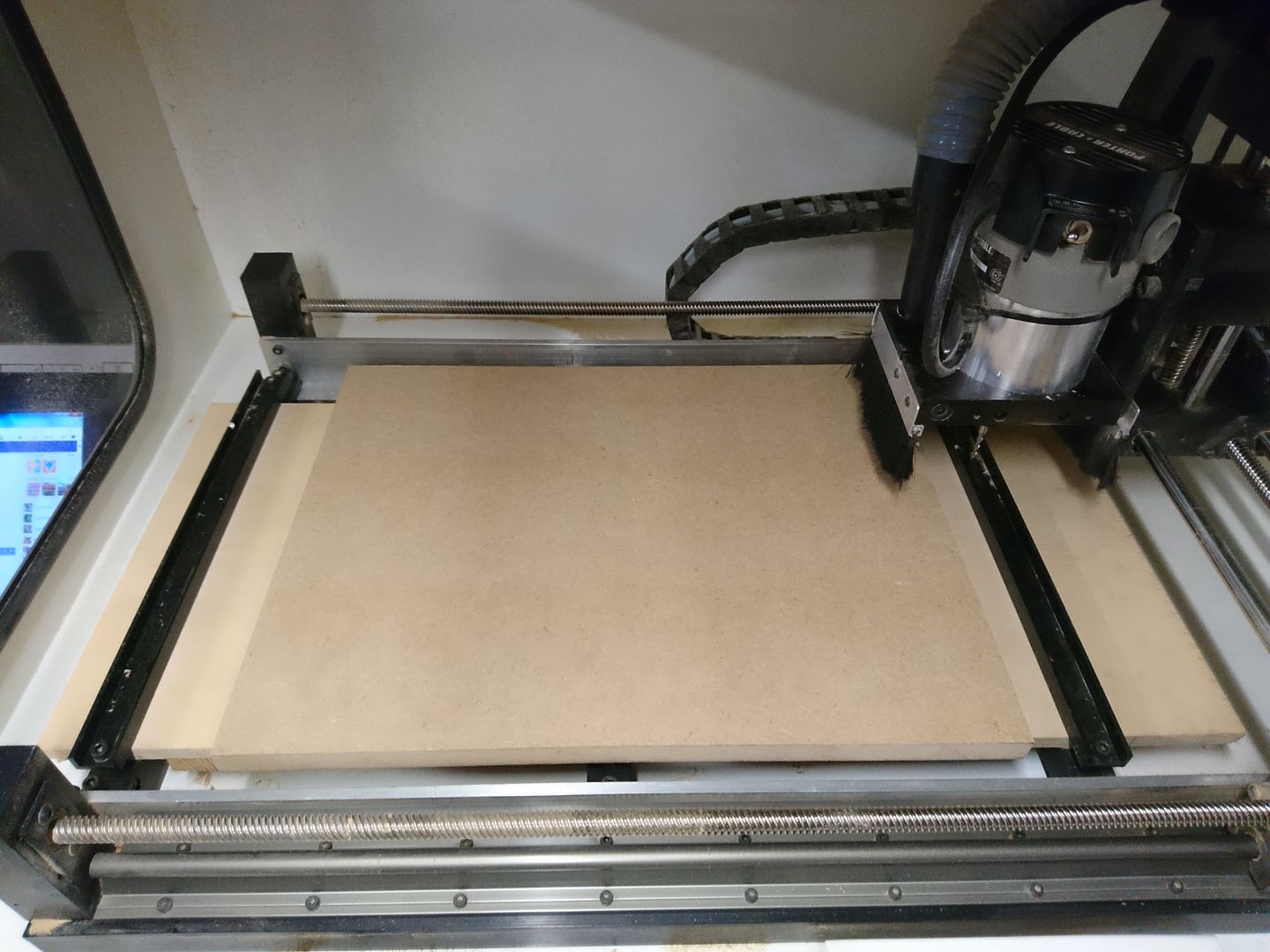

First bit if work completed

-

The Following User Says Thank You to andy_con For This Useful Post:

-

08-06-2016 #43

Ready for painting

-

The Following User Says Thank You to andy_con For This Useful Post:

-

09-06-2016 #44

Looking good Andy!

.MeLee

-

The Following User Says Thank You to Lee Roberts For This Useful Post:

-

09-06-2016 #45

if the motor is 8 wire, then 3A is the unipolar current and 2.1 is in series and it will be 4.2 in parallel. this is typical for 8 wire motors.

-

10-06-2016 #46

Ah ah this Makes a change from me being the one clashing heads but rest assured if I hadn't been busy I'd have blasted you just the same.!! . . .Your very out of order Calling MC a Troll. He's one of the nicest and most helpful people on the forum who's replys are considered and well thought out with healthy dose of common sense applied.

He's absolutley Correct in what he was saying, Know this because I'm often the one cleaning up when people with little to no experience dish out advice with such authority that unsuspecting people often desparate to resolve problems fall hook line sinker and take it on board. Only to find out that person was full of shit.!!

Like MC this is also one of my pet hates and like him I'll always jump on people who do this because it's not helping anyone but the Ego of the tosser who's spouting bull shit.!

Have bit more respect for nice guy and don't be so quick to dishout advise if don't know what your on about.!

Andy Con.

I haven't read all the thread so not upto speed but I recently converted a Denford router to mach using exisiting motors but with New digital drives and the motors run at worst just little more than warm while cutting. At stand still they are stone cold.

All this talk of Controller handling Current reduction is bullshit, 99.9% it's function of the drive that works regardless whether Mach or PC working or not. Drive just sense's for signals and goes into stand by if not recieved any within period of time.

I'd be checking settings and Motor phase wiring because with only 36v you shoudn't be getting hot. That said how hot is hot did you take temp reading.?

PS: Nice work on the signs.

Last edited by JAZZCNC; 10-06-2016 at 12:04 AM.

-

The Following User Says Thank You to JAZZCNC For This Useful Post:

-

10-06-2016 #47

Andy,

That all looks great, but have you considered adding a V-carve type path about 4mm deep with a V-bit cutter for the outlines?

That would give you near pin-sharp corner definition on characters and graphics where they merge and the cutter diameter cannot manage sharp corners,

Regards,

NickLast edited by magicniner; 10-06-2016 at 12:53 PM.

You think that's too expensive? You're not a Model Engineer are you? :D

-

10-06-2016 #48

-

10-06-2016 #49

the machine only came with a single 6mm collet so im limited to 6mm shank tools at the moment. ive ordered some more collets from the us which im waiting to arrive, once I get them I can start using more tools.

that engraving one done with a v-bit router tool, but only 0.3mm deep. were I to have the right collet I would have done it 1mm deep with a 1mm end mill

im pretty new to wood, so still learning what gives the best results. ive since painted that engraving so its looks much better now

-

10-06-2016 #50

-

The Following User Says Thank You to magicniner For This Useful Post:

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

FOR SALE: Denford Starmill ATC

By andy_con in forum Items For SaleReplies: 1Last Post: 14-02-2016, 10:16 PM -

1999 Denford Microrouter problems

By D-man in forum Denford RoutersReplies: 5Last Post: 21-03-2015, 12:43 PM -

Denford MicroRouter Compact, what to do next?

By paul_m in forum Denford RoutersReplies: 2Last Post: 08-01-2015, 09:51 AM -

FOR SALE: Denford cnc

By john legge in forum Items For SaleReplies: 4Last Post: 17-03-2013, 11:18 PM -

Denford CNC MicroRouter

By mekanik in forum Milling Machines, Builds & ConversionsReplies: 12Last Post: 27-08-2012, 06:57 PM

Reply With Quote

Reply With Quote

Bookmarks