Threaded View

-

07-02-2016 #1

looking at doing a complete over hall of the 6 station atc on my triac.

I want to change the 6 tool holders to 10 and replace the slow motor that only spins one way with a decent stepper that can go both ways.

all the designing is done and ive hit a stumbling block which I need some help on - a pulley system.

the shaft of the nema isnt long enough to stick out the bottom of the mounting part.

so not sure how im going to get a toothed pulley system to do the job.

but that's all I need is 2x toothed pulleys and a belt of the right length.

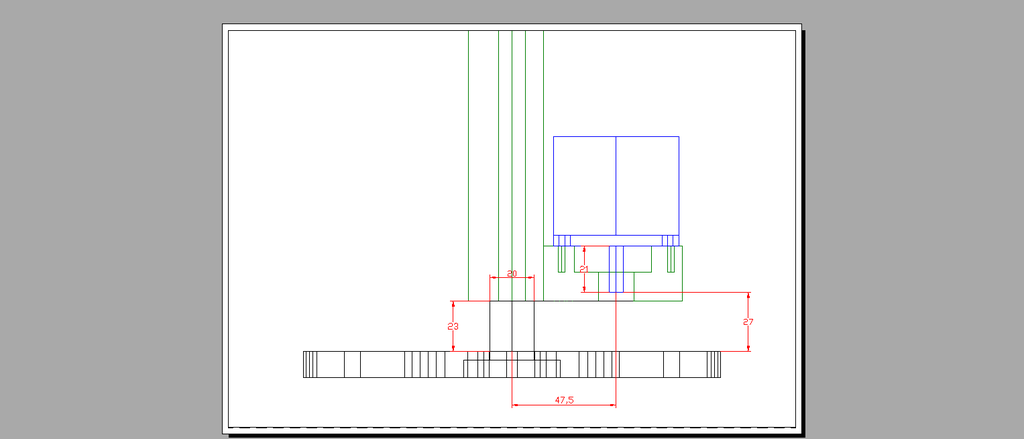

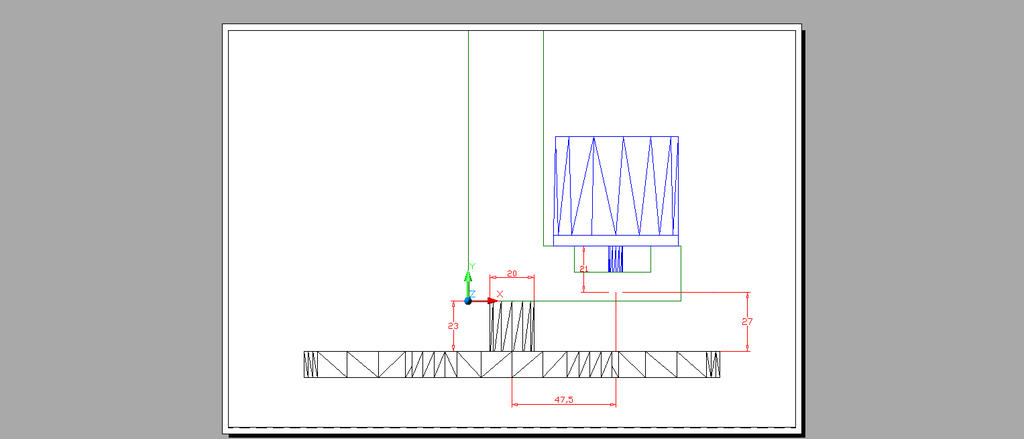

as you can see from the drawing two centres are 47.5mm apart

green = part of existing atc arm

blue = new nema

black = new 10 station tool holder

red = dimensions

see through -

solid version

you can just see the atc to the left here

sorry got the white cover on

Last edited by andy_con; 07-02-2016 at 09:32 PM.

Thread Information

Users Browsing this Thread

There are currently 3 users browsing this thread. (0 members and 3 guests)

Similar Threads

-

Hewing hall millgrav

By cncezee in forum Milling Machines, Builds & ConversionsReplies: 26Last Post: 19-12-2020, 07:16 AM -

EXPERIENCE: CorkCNC custom part

By MarkLeeds2K5 in forum Trading Experience & FeedbackReplies: 0Last Post: 28-01-2016, 06:43 PM -

RFQ: Custom CNC work - Just wondering how much...

By Mustang80 in forum Projects, Jobs & RequestsReplies: 0Last Post: 02-10-2011, 07:53 PM -

pulley ratios on 3 pulley axis

By Swarfing in forum Belt Drive, Pulleys & TimingReplies: 35Last Post: 21-07-2011, 12:43 AM -

Custom power DC supply

By M250cnc in forum Electronic Project BuildingReplies: 11Last Post: 22-11-2010, 09:48 PM

Reply With Quote

Reply With Quote

Bookmarks