-

14-08-2010 #41

ok so im just about to buy a board from DIYCNC, what one do you suggest is best for my application?

-

14-08-2010 #42

System 1 plus the plug in spindle speed board, that one is advertised under the System 4 setup.

Same board used in both, cheapest and most cost effective.

No need for an opto board if you are using Gecko's or similar drives as the drives have this function.John S -

-

14-08-2010 #43

Cheers john...

-

15-08-2010 #44

UPDATE!

So today i thought i would start to run through everything on the board with the steppers, starting with the Data cable.

This cable ahs been chopped and soldered back together very badly. i got my soldering kit out, and redid some of the wires that were looking crap. taped up all of the ends so non could touch.

Tried moving the motors about and ..... they worked fine. this put a smile on my face.!!

So then to the CNC4PC C1G Board.. Made sure all the connections were soldered and clamped in correctly. yup everything is fine.

Gecko's.. Well these are not my fav tbh but they work for now.. So again made sure all the ends were soldered and clamped correctly.

Lastly to the motors.. Soldered, clammped and secure!

gave the whole machine a good go and it wasnt tripping the PSU.... So rished down stairs and ordered a new cable, 18k resistors and now im looking at some new tooling..

What do you guys suggest for the tooling, i was looking at the indexable ones with carbide tips

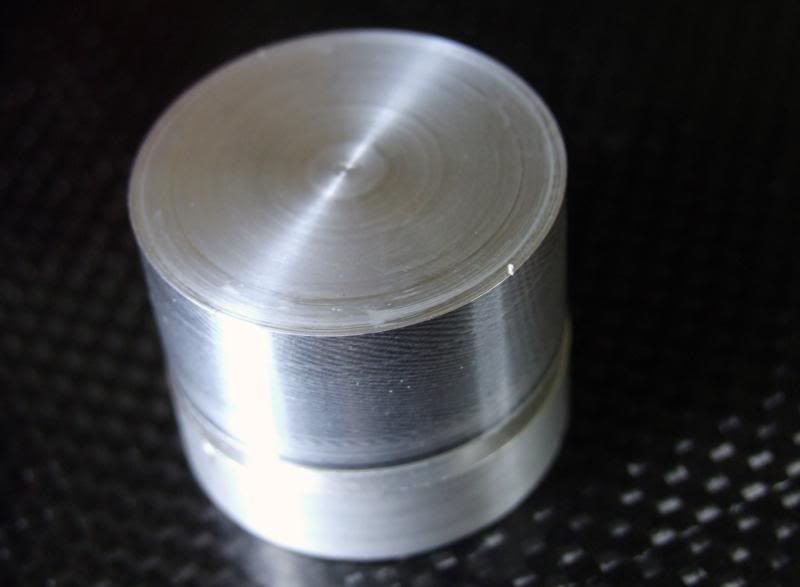

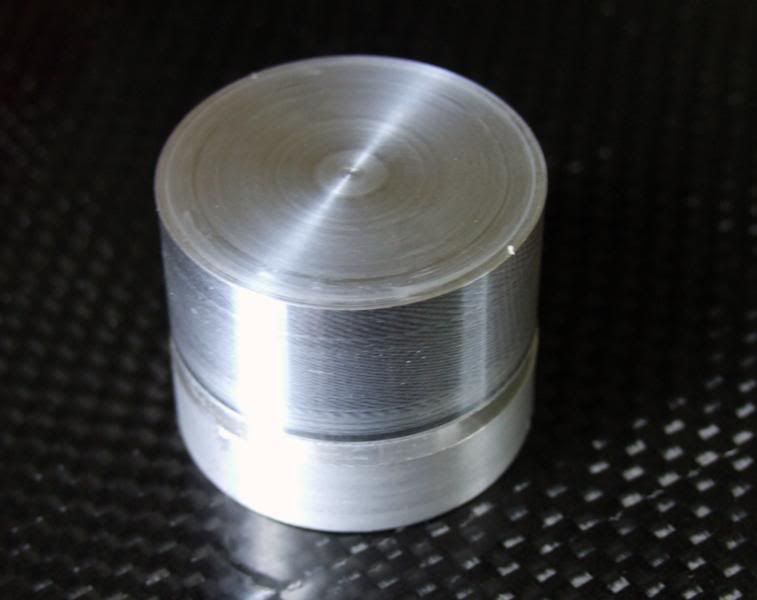

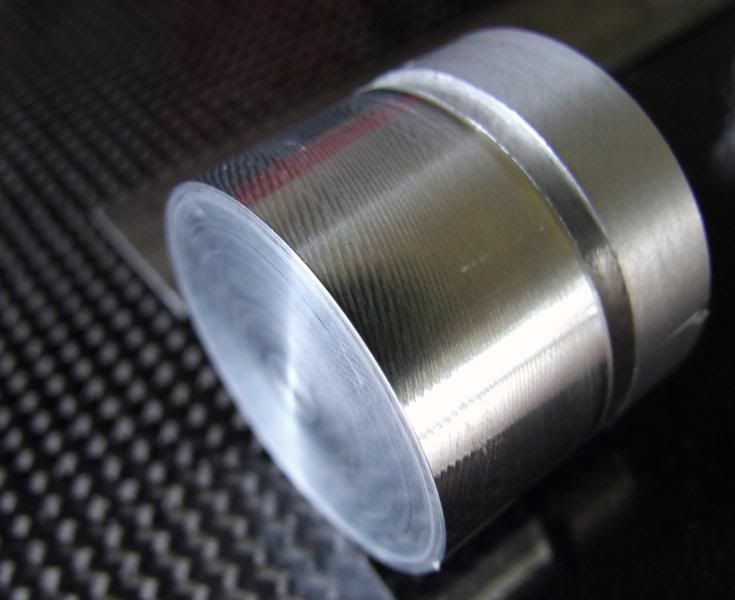

Also, this was a quick (manual) test

Getting closer to having it done!

-

15-08-2010 #45

how far from the chuck was the ally, as there's a lot of chatter on the job. Could be the gibs need setting

-

15-08-2010 #46

you see in the last pic on the back side there is a mark, thats where the chuck marks were.

Tbh i think the tool is about as sharp as a cricket ball! and it might have been loose? i need to make sure everything is nice and tight next

One more questions, where do you get the center drilling attachment from?

-

15-08-2010 #47

yes i see the marks, must be the tooling. Don't scrimp on the tooling when you buy, indexable tips and you need to spend around £20 per tool minimum. The cheap indexable sets are garbage.

-

15-08-2010 #48

does this machine have a rotary toolpost or a dixon

-

15-08-2010 #49

yeah fully understand that... ive probably got some shite tooling and its crap.

dont really wanna be buying it of the bay then?

-

15-08-2010 #50

its not rotary, its a fixed quick release one.

Dixon?

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Can't reply to a thread

By Washout in forum General DiscussionReplies: 9Last Post: 24-10-2012, 06:56 PM -

Thread Engagement

By GTJim in forum General DiscussionReplies: 1Last Post: 12-09-2012, 11:13 AM -

Thread Tapping?

By Tenson in forum Tool & Tooling TechnologyReplies: 6Last Post: 04-05-2012, 04:51 PM -

Thread diameter

By Daniel in forum General DiscussionReplies: 7Last Post: 23-02-2012, 06:18 PM -

Pipe thread in 22 tpi???

By Robin Hewitt in forum Machine DiscussionReplies: 3Last Post: 21-09-2010, 11:19 AM

Reply With Quote

Reply With Quote

Bookmarks