-

19-10-2014 #31

-

23-10-2014 #32CNC routing and prototyping services www.cncscotland.co.uk

ADD ME ON FACEBOOKS

ADD ME ON FACEBOOKS

-

23-10-2014 #33

Hi Gav

Yes it's made from silver steel which is a high carbon steel available in metric & imperial sizes and is ground finish and readily available. The bar is in it's annealed state and you manufacture your required tool then heat it to cherry red and quench, then polish the tool and apply heat to the end of the shaft and you will see the polished surface change to a straw color as this works it's way to the cutting part of the tool quench in cold water and that's it tempered.

Looking @ your drawing that profile is situated in the sliding part of the jobby that the mould goes into,is that correct ?

-

23-10-2014 #34

Making those kinds of countersink bits in silver steel on a Myford is fine - done it plenty of times myself. The biggest issue is machining the half-diameter; you can file it, but I used my Myford milling slide to machine it. Even easier if you have access to a milling machine. If you make a slight undercut just where the cutting surfaces meet the full diameter, you end up with a flat surface that is easy to touch up on a stone if needed. Hardening is one of those odd things that sounds very difficult and technical but is actually very straightforward when you do it. Main thing, as Mekanik said, is to heat the shank. not the tip, and watch the colours travel towards the cutting edges, but don't use too much heat as the travel can be a bit too quick. If that does happen, you can always try rehardening (cherry red and quench) and then have another go at tempering. Silver steel properly hardened and tempered actually cuts mild steel surprisingly easily; what it can't take is heavy/fast cutting which overheats the cutting edges and destroys the tempering. That's one reason HSS was invented - holds its temper even when pushed hard.

-

24-10-2014 #35

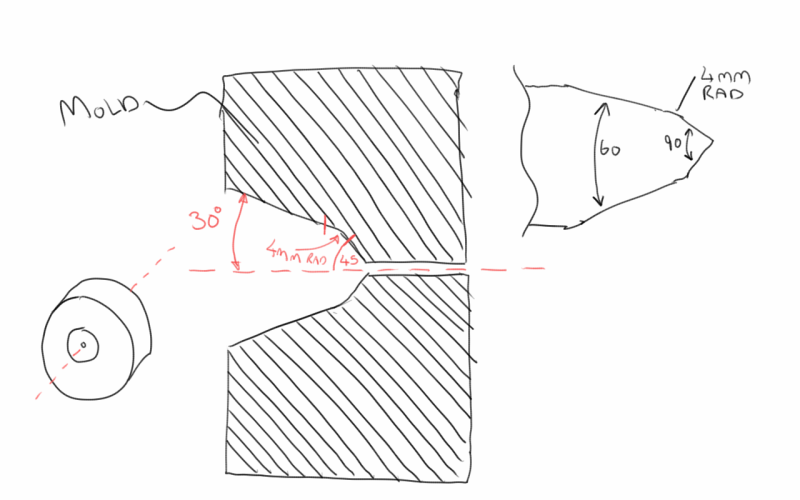

I dont know if this drawing makes it more or less confusing?Last edited by gavztheouch; 24-10-2014 at 06:08 PM.

CNC routing and prototyping services www.cncscotland.co.uk

ADD ME ON FACEBOOKS

ADD ME ON FACEBOOKS

-

24-10-2014 #36

Let me go through the theory so that anyone here who is not au fait with sprues can keep up.

The mould is in two halves which bolt to two plates in the moulder. The plates are called platens.

There is a fixed platen which you can move by handscrew to allow for different height moulds.

There is a moving platen which winds back when the moulding operation is complete so you can get the part out.

The fixed platen has the ejector pins coming out through it to free the part when the mould is open. So it is very important that the part stays with the fixed platen on opening or everything is going to go horribly wrong.

Coming up through the middle of the moving platen is the injection nozzle which has a whole mess of molten plastic behind it and some kind of piston arrangement that is going to force it out. It's a bit like a hot bicycle pump.

So, the mould closes, the nozzle connects, the plastic is injected. It has to get to the heart of the mould to form the part.

The initial pipe that carries it will end up full of cold plastic. The plastic in that pipe forms the sprue.

If you are still reading, well done, you will now appreciate the problem, the sprue is moulded on the moving platen side but it must stay attached to the fixed platen side when the mould opens. Obviously anything that helps it slide out is good.

First thing you do is make the sprue using a tapered hole and polish it inside.

Next thing is to make the injection nozzle big and hot so the mould never manages to chill it. If the plastic strings a bit when the nozzle retracts that is good. If it strings too much you might need a puff or air to freeze it.

If the sprue connects to runners rather than directly in to the part you can fit a sprue extractor to the fixed platen side of the mould. A sprue extractor is a conical dent widening in to the mould with a monster ejector pin at the bottom to force it out once it has done it's bit. You have to make sure that the whole sprue comes out. If the sprue breaks and leaves anything of itself behind then we have to hope the machine can detect it.

If you are still reading you should be up to speed.

The European nozzle is usually hemispherical and goes in a hemispherical sort of dent. There is no flat end to the nozzle because that would mould a nail head on the top of the sprue and make it hard to pull. That is why I don't understand why this machine seems to have a flat.

This machine has a relatively tiny nozzle diameter so is there a real risk of it freezing? Perhaps it is supposed to freeze, pull the nail head and the remelt it? Perhaps the nozzle is floating and the conical cutout is to guide it? Obviously it must work or they would have done it differently, but I am still puzzled.

This needs to be understood before trying to make a mould.

-

The Following User Says Thank You to Robin Hewitt For This Useful Post:

-

24-10-2014 #37

Excellent post Robin.

Perhaps a picture or two of the actual nozzle may help clarify things. I can't get my head around why the gate is quite so elaborate, unless the machine relies on it to actuate something as part of the injection process.Avoiding the rubbish customer service from AluminiumWarehouse since July '13.

-

25-10-2014 #38

Thanks for the post Robin.

yeah i think a video or picture of the machine might be handy, might be able to do that this morning.

I have a feeling the gate is elaborate because you need the wide 90 angle near the "spreader tip" but if you carried that 90 degree angle back to the sealing face it would be too wide, so I think they went with 60 degrees thereafter and blended the two together with a 4mm rad just to keep things smooth?

I think from Robins description, my machine works by holding/retaining the part in the moving half of the mold, the fixed halve is held against the nozzle permantly. So when the platens open the part is pulled away from the fixed halve and the sprue is pulled out through the 1mm hole, leaving a molten mess of plastic in the gate.Last edited by gavztheouch; 25-10-2014 at 10:03 AM.

CNC routing and prototyping services www.cncscotland.co.uk

ADD ME ON FACEBOOKS

ADD ME ON FACEBOOKS

-

25-10-2014 #39

To understand gates you only have to remember the good old Airfix model kit. The framework holding the parts are the runners, the narrow bits you snip through to release the parts are the gates. The plastic is injected. Wherever it touches the mould it freezes, but it freezes from the outside in, a bit like a water pipe furring up at super fast speed. So long as the plastic flows it can get heat and keep a channel open, if it stops flowing then it freezes and ends the injection process. The gates restrict the flow locally so flow doesn't stop anywhere until the mould is full. Clever stuff sizing the gates in an Airfix mould, kinda makes you stand back in awe.

-

25-10-2014 #40

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Plastic injection mold making forum?

By gavztheouch in forum Moulding MachinesReplies: 26Last Post: 13-10-2022, 11:31 AM -

New toy - Arburg injection moulder

By Robin Hewitt in forum Moulding MachinesReplies: 13Last Post: 26-10-2014, 11:59 PM -

RFQ: Any Injection Moulders on here, before I buy Chinese ?

By Bazzer in forum Projects, Jobs & RequestsReplies: 11Last Post: 18-05-2013, 11:25 AM -

DIY Injection moulding by JR Hartley.

By HankMcSpank in forum Moulding MachinesReplies: 26Last Post: 04-01-2013, 12:41 AM -

Proxxon MF70 for making injection molds

By forrest in forum Moulding MachinesReplies: 8Last Post: 11-04-2012, 11:30 PM

Reply With Quote

Reply With Quote

Bookmarks