-

27-04-2017 #121

-

27-04-2017 #122

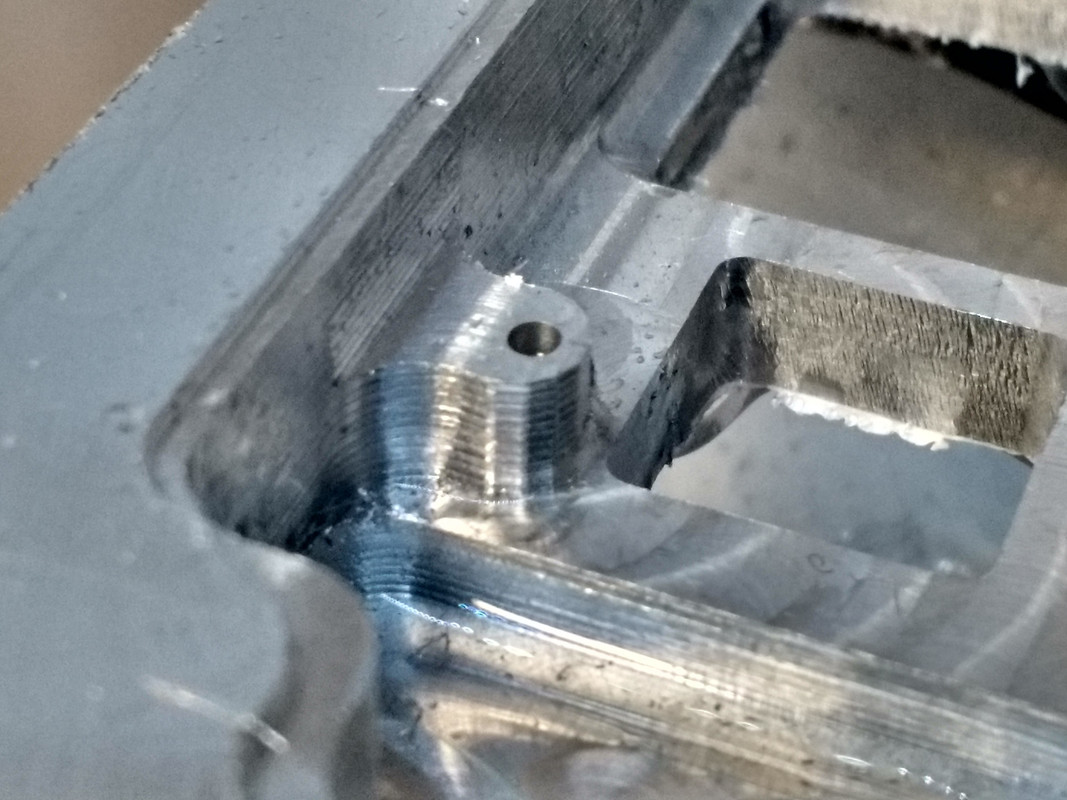

Well you can't make a square hole with a round bit, so if you need it more square use a smaller bit.

..Clive

..Clive

The more you know, The better you know, How little you know

-

27-04-2017 #123

-

28-04-2017 #124

-

28-04-2017 #125

-

30-04-2017 #126

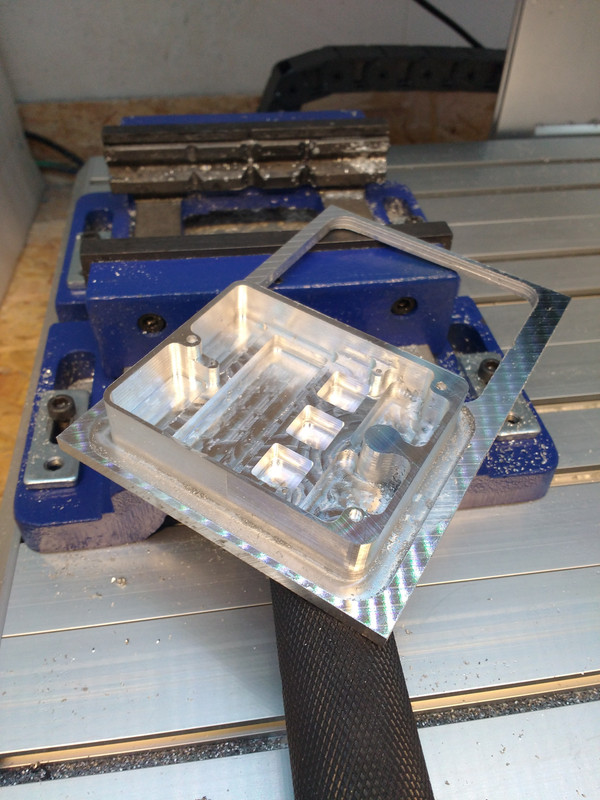

Not perfect but I think I have got it down pretty well.

I don't have a 3D probe yet so whenever I reset the machine I am obvious out somewhat.

The last operation of cutting out the case was well out for some reason..

I am working now on setting up a spoil board underneath the stock to then super glue my stock to.

This means I am not cutting out something floating in mid air.

Just another bit of aluminum stock will do that I can then glue my work stock onto with super glue?

-

30-04-2017 #127

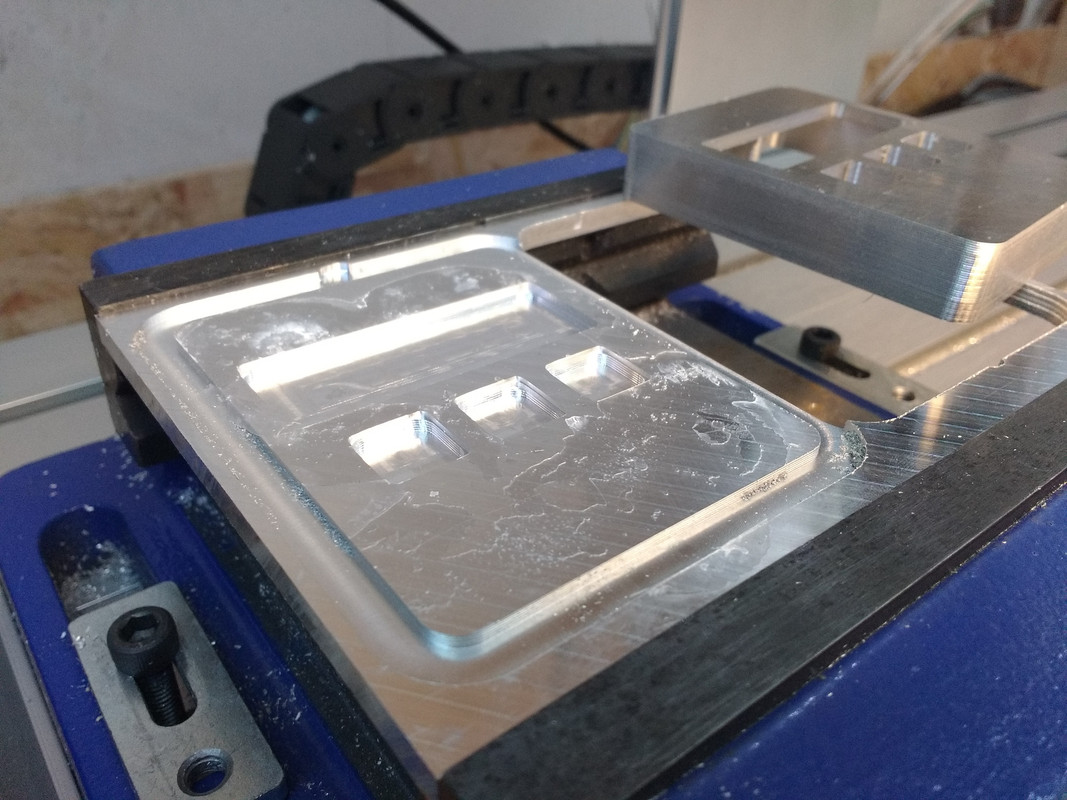

Well superglue worked really well.

Surprised how quickly the two bits stuck together as soon as I got the air out of the gap.

Much better than cutting in the air.

Main problem atm is the water.

Thinking of building a dedicated table for the machine which is basically a drip tray that I can then have doors on each side and all the stuff bellow like the controller, spindle cooling res, cooling water etc.

Means I can flood cool too. Which will be quieter than using the air compressor.

Thoughts?

-

02-05-2017 #128

We are cutting steel on mills with mist so not to use coolant and you are going backwards. Cooling with liquid is nice for a production setup but for home? The less, the better. Mist is better for home. Do it properly as i have made it and there will be no problem. With one nozzle you can cool up to 25mm bits.

-

The Following User Says Thank You to Boyan Silyavski For This Useful Post:

-

03-05-2017 #129

Thinking about it you are right.

Going to make a bed for the CNC that can hold the water that comes off the mist.

I actually had the bottle about a meter above the cnc the other day and just the water alone worked fine by the looks of it.

No air just gravity fed water.

Anyone tried these?

https://www.shop-apt.co.uk/corner-ro...ide-45hrc.html

There are 2 Flute ones but only in the US from the looks of it.

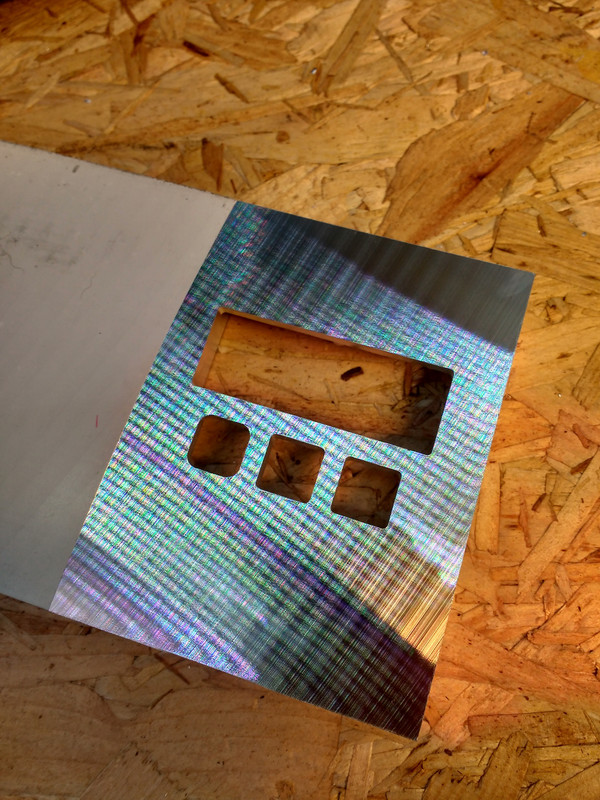

I need to put a nice round edge on my product housing and these look to be the only thing available.

-

03-05-2017 #130

Thinking about it you are right.

Going to make a bed for the CNC that can hold the water that comes off the mist.

I actually had the bottle about a meter above the cnc the other day and just the water alone worked fine by the looks of it.

No air just gravity fed water.

Anyone tried these?

https://www.shop-apt.co.uk/corner-ro...ide-45hrc.html

There are 2 Flute ones but only in the US from the looks of it.

I need to put a nice round edge on my product housing and these look to be the only thing available.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

New 6040 owner looking for advice from others with a chinese 6040/3040

By itsmillertime in forum Machine DiscussionReplies: 12Last Post: 14-10-2019, 08:30 AM -

Newbie question re converting my 6040 machine to use a laser

By GaryWilliams in forum Laser Machines & BuildingReplies: 2Last Post: 19-10-2015, 03:09 PM -

10 / 15mm thick 6061 aluminium alloy sheet ?

By rnr107 in forum Marketplace DiscussionReplies: 10Last Post: 14-01-2014, 12:15 AM -

FOR SALE: Polypropylene compound

By Bjh1985 in forum Items For SaleReplies: 0Last Post: 08-09-2013, 09:39 AM -

NEW MEMBER: Newbie From China

By jenniferxu in forum New Member IntroductionsReplies: 1Last Post: 04-01-2011, 06:02 PM

Reply With Quote

Reply With Quote

Bookmarks