-

20-11-2019 #1

Hello All!

I'm in the planning stages of a mini lathe made from epoxy granite. Nothing fancy and not a heavy duty machine.

I have a few INA 20mm linear carriages and rail and a couple of THK 25mm carriages and rail (one short piece really). I thought I might put them to good use. I will be cutting plastics, brass, aluminium and possibly the odd mild steel part. I'm not sure yet if I NEED a tailstock yet.

Body is epoxy granite. Headstock is built into the EG and will be using taper roller bearings or angular contact. Chuck will probably be 80mm on a 25mm shaft.

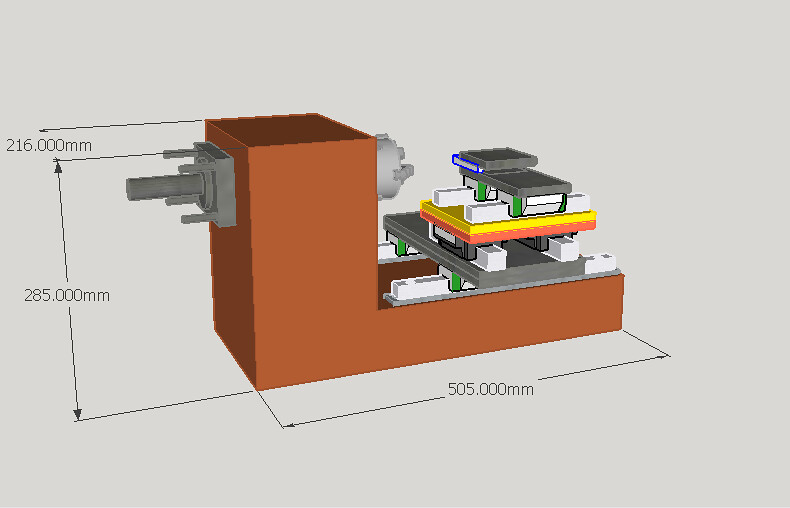

Here are screenshots of my crappy sketchup model showing what I'm thinking. Does anything stand out to you folks as being missing? There are no ballscrews for travel modelled yet.

Thanks

NealLast edited by Nealieboyee; 20-11-2019 at 10:20 PM.

-

21-11-2019 #2

You have modelled a compound. You don't need one and it would reduce rigidty.

The compound exists on manual lathes to allow angles / tapers.

-

21-11-2019 #3

-

21-11-2019 #4

Parts made for CNC (linear bearings and ball screws) are not suited for a manual machine.

You will likely get back driving / unintentional movement.

-

21-11-2019 #5

What Pippin said, also, I'd review the bed length - you mention turning tapers which generally implies a component of "some" length - it looks like your bed is in the order of 300mm, with a compound slide and chuck somewhere in that space - there won't be much travel left.

-

21-11-2019 #6

What would you recommend replacing the linear carriages with for sliding?

-

21-11-2019 #7

Linear rails and carriages will work - but you know that.

You're adding a lot of unnecessary height to the cross/top slides and the resultant increase in height of the spindle above the bed. I'm probably talking out of my arse here but the force on a cutter in the top slide lathe are a lot more predictable than a mill - typically with just about a single vector - are there no more appropriate systems than square rail for this application? That said, if you have the rail already....

If you want to cut tapers, and reduce your overall height - look at existing taper attachments for lathes (you need to be able to decouple the cross slide from the screw). You can lose the compound with this.

My main agreement with Pippen though is the amount of back-drive. Even on my somewhat light-weight ML7 you need a carriage lock to avoid back-drive on the original acme thread (I've yet to assess this on a ball/belt/stepper combo). My main, main issue though is bed length. If you know that this is sufficient for your need then go for it, but I can't help but think that you're going to be limited to something not much more that 100mm Z travel once you've finished.

EDIT: Cold light of day: back-drive - not with the spilt nut engaged (hence acme thread) - my bad, disregard - I had to lock the carriage to avoid back-drive against the rack-and-pinion of the carriage position wheel.Last edited by Doddy; 22-11-2019 at 08:46 AM.

-

22-11-2019 #8

The other thing to think about is how you will align the tool height to the spindle centre. If you are going very simple then the surface the tool sits on needs to be on the low side so you can shim up to suit each tool. You can't shim down.

More complex arrangements are a quick change tool holder with a threaded height adjuster per tool. I would have a look at this option as it makes tool changes quick without dialing them in each time or keeping a set of shims per tool.

-

22-11-2019 #9

All valid points. As you said, I already have the carriages and rail. I do have some acme thread I pulled out of a reclining couch a while ago. I can try to make some nuts for it. Either that or I can lock the ballscrew somehow to prevent backdrive.

I'll definitely lengthen the bed. I will lower the cross-slide and do away with tapers then. Perhaps design it to take a quick change tool holder.

This is just experimentation for me. I've always wanted a lathe and also to try my hand at epoxy granite. So why not. Not needing anything massive though.

Thanks

-

23-11-2019 #10

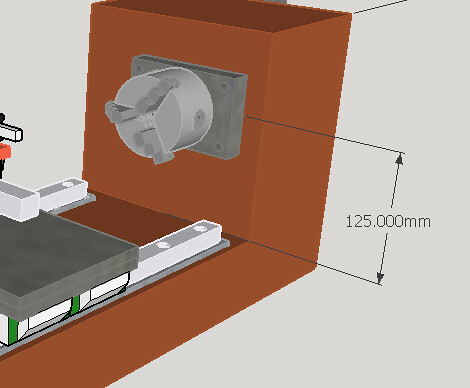

Right, changes have been made. No compound slide, bed is longer by 160mm, and QCTP added. The distance from bed to chuck center is now 125mm, around 25mm lower than before.

How we looking?

Cheers

Neal

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

BUILD LOG: Epoxy granite vertical mill build log

By Nick in forum DIY Mill Build LogsReplies: 60Last Post: 08-06-2020, 06:30 AM -

Large Format Epoxy Granite Gantry CNC - Looking For Feedback

By Max Maker in forum Gantry/Router Machines & BuildingReplies: 5Last Post: 23-08-2019, 04:57 PM -

SOLD: Hobbymat MD65 mini lathe and BF65 mini mill

By Boyan Silyavski in forum Items For SaleReplies: 3Last Post: 03-11-2018, 12:45 PM -

Epoxy granite or mineral casting

By mike mcdermid in forum Gantry/Router Machines & BuildingReplies: 46Last Post: 20-02-2014, 06:21 PM -

Epoxy Granite Molds?

By gavztheouch in forum Moulding MachinesReplies: 8Last Post: 18-02-2014, 07:28 PM

Reply With Quote

Reply With Quote

Bookmarks