-

31-03-2017 #61

Went with the X6.

Don't really need the size of the X8, yet :p

Ordered a full set of collects and some 1mm and 3mm bits.

Looking at vices, got 2 cheapo ones from Ali, they look okay but not proper strong.

Will see if they work okay or not. If not, can use them for lighter material at least.

-

11-04-2017 #62

Not fully set up yet. Wish the cables were longer so I could have the controller elsewhere.

Done some tests and it looks to work well.

Just got to get some distilled water and some bits for my air compressor and we should be good to go!

The whole rig feels super strong. Not like steel strong but nothing moves if you push against any faces.

The only thing that came broke was the infamous pump...

Last edited by JOGARA; 11-04-2017 at 11:47 PM.

-

12-04-2017 #63

interesting, few design tweaks from mine - they are using a different kind of alu for the side arms (mine doesn't have that channel in the front edge) and looks to be using HIWIN, or HIWIN copy I suppose, carriages where mine was using something else.

Glad it all arrived safely, have fun!

Monster thread on CNCzone about that machine, has some good info in it.

-

The Following User Says Thank You to Zeeflyboy For This Useful Post:

-

12-04-2017 #64

Not read threw that thread yet. On my todo list :p

Cut some wood this evening to test it all out.

(Obviously not cleaned it up or used a 2nd op to chamfer it. "Dog Shed" is what we call my workshop fyi, because the dogs live in it)

Worked really well. Went from Fusion 360 to this in no time.

Water got a bit warm. Using 15L of Halfords de-ionised battery topup water.

What temp should I be concerned at? A few places are saying 30-35C max. I have another 15L worth but I need some for my laser (obviously can go get more).

Thinking I might make a single 60L system with 2 pumps (one for each tool) and also a radiator with fans on to circulate the 60L tank with air cooled water.

Wont really be using both at the same time, but rather have one large tank of water than the two if it is okay to do so.

My Ecocast from Aliwarehouse also arrived. Had some concern about these guys from reading a few threads on here but this lot came in 2 days without a blemish on them.

-

12-04-2017 #65

Downcut bits will avoid that rough edge that you can get on wood like that, might be worth picking some up. Work well on plastics too for the same reason.

I've always found aluminiumwarehouse ok.

I wouldn't over-think the cooling... there isn't that much heat to dissipate. Mine works fine with a small closed loop system (basically a single PC water cooling radiator and pump). Certainly no need to have a 60L system AND a radiator.

If you want to have a big combined cooling system for both your laser and your CNC then sure, why not. Seems to be over-complicating things though.Last edited by Zeeflyboy; 12-04-2017 at 11:14 PM.

-

The Following User Says Thank You to Zeeflyboy For This Useful Post:

-

13-04-2017 #66

-

The Following User Says Thank You to Boyan Silyavski For This Useful Post:

-

13-04-2017 #67

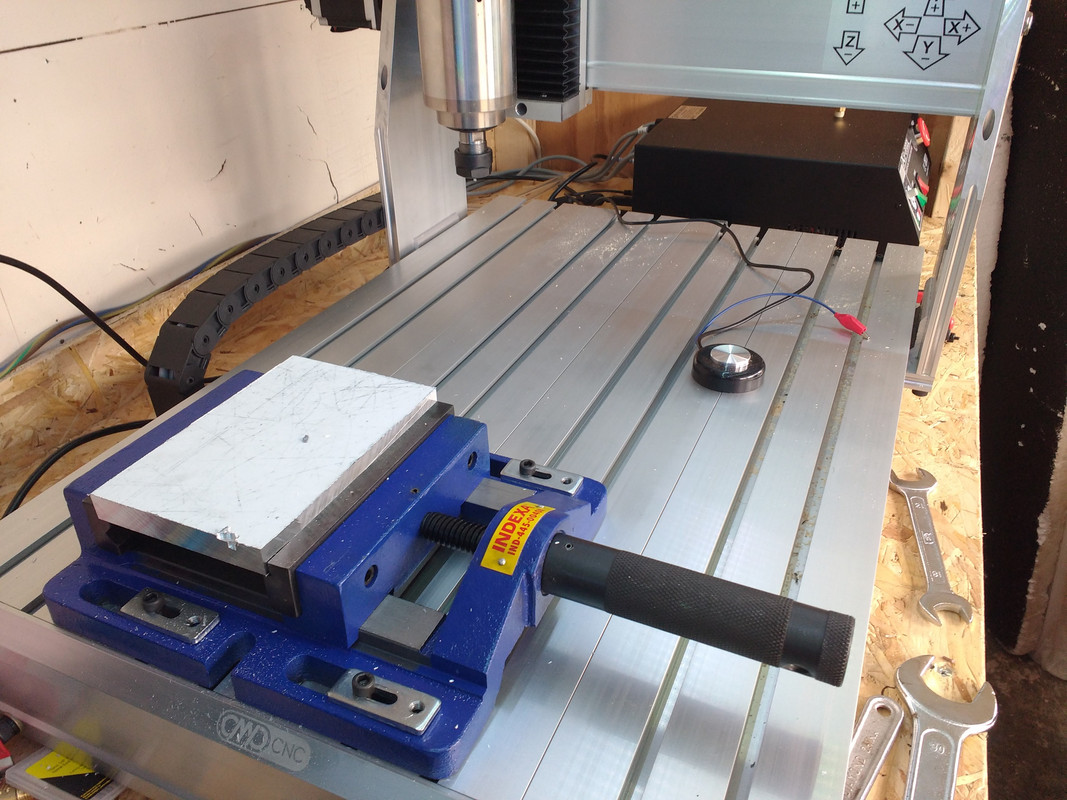

Just got my new vice. Decided against the 2 cheap ones from China that cost £100. Went with a single one for £80 that is built for "light milling". Feels solid enough for what I need.

Holds my 150x100 aluminium perfectly and there is room to put bigger bits in there.

Will work on the mounting of it to the base though.

Only getting 1-2 hours a night to play with it all atm.

Got to finish a load of uni work :/

Also need to work on my speeds and feeds...

-

13-04-2017 #68

looks like it should be fine.

Just beware that your bed won't be level, so bolting the clamp directly to the bed won't give you a level surface either.

Ideally you need to bolt on a spoil board of some description and use the machine to skim it down. That will give you a flat surface to screw the clamp down into.

-

13-04-2017 #69

-

13-04-2017 #70

MDF or similar would be ok as long as you aren't using much coolant. If you have any moisture resistant lying around that is a bit more stable in terms of dimensions and changes in humidity etc but far from essential.

You could also just bolt down a small piece where you intend to put your vice, rather than the whole bed. You would just have to re-skim it if you remove it but that's not a big deal for a small piece like that.

-

The Following User Says Thank You to Zeeflyboy For This Useful Post:

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

New 6040 owner looking for advice from others with a chinese 6040/3040

By itsmillertime in forum Machine DiscussionReplies: 12Last Post: 14-10-2019, 08:30 AM -

Newbie question re converting my 6040 machine to use a laser

By GaryWilliams in forum Laser Machines & BuildingReplies: 2Last Post: 19-10-2015, 03:09 PM -

10 / 15mm thick 6061 aluminium alloy sheet ?

By rnr107 in forum Marketplace DiscussionReplies: 10Last Post: 14-01-2014, 12:15 AM -

FOR SALE: Polypropylene compound

By Bjh1985 in forum Items For SaleReplies: 0Last Post: 08-09-2013, 09:39 AM -

NEW MEMBER: Newbie From China

By jenniferxu in forum New Member IntroductionsReplies: 1Last Post: 04-01-2011, 06:02 PM

Reply With Quote

Reply With Quote

Bookmarks