Threaded View

-

27-11-2017 #7

Trying to reduce the force that is pulling down the bit.

The thing I changed when it started to happen was that I went from 1mm DOC to 1.5mm DOC.

So I am changing that back (sadly the 1.5mm DOC halfs my machine time which is why I want it).

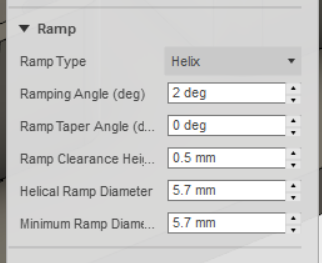

Wondering if the helix is also too much? It sounds nasty when it does it but that could be down to the machine rigidity?

I am tempted to grab a 8mm carbide drill bit and use that to get as far down as possible and use that hole as the "pre drill position"Last edited by JOGARA; 27-11-2017 at 03:39 PM.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

New 6040 owner looking for advice from others with a chinese 6040/3040

By itsmillertime in forum Machine DiscussionReplies: 12Last Post: 14-10-2019, 08:30 AM -

Newbie question re converting my 6040 machine to use a laser

By GaryWilliams in forum Laser Machines & BuildingReplies: 2Last Post: 19-10-2015, 03:09 PM -

10 / 15mm thick 6061 aluminium alloy sheet ?

By rnr107 in forum Marketplace DiscussionReplies: 10Last Post: 14-01-2014, 12:15 AM -

FOR SALE: Polypropylene compound

By Bjh1985 in forum Items For SaleReplies: 0Last Post: 08-09-2013, 09:39 AM -

NEW MEMBER: Newbie From China

By jenniferxu in forum New Member IntroductionsReplies: 1Last Post: 04-01-2011, 06:02 PM

Reply With Quote

Reply With Quote

Bookmarks