Thread: Thor, or should that be Zeus?

-

28-05-2017 #221

A long shot, anyone near Uxbridge (I am willing to travel) that has a mill that I can use to get this Z Axis completed?

I need something that can do around 500 x 400 mm. I have access to a Bridgeport but no response from the person that offered. I just need to go around the rectangle and square up and do around 16 holes with some very basic code.

Thanks

-

30-05-2017 #222

Last edited by Desertboy; 30-05-2017 at 07:24 AM.

http://www.mycncuk.com/threads/10880...60cm-work-area My first CNC build WIP 120cm*80cm

If you didn't buy it from China the company you bought it from did ;)

-

30-05-2017 #223

-

The Following User Says Thank You to Chaz For This Useful Post:

-

30-05-2017 #224

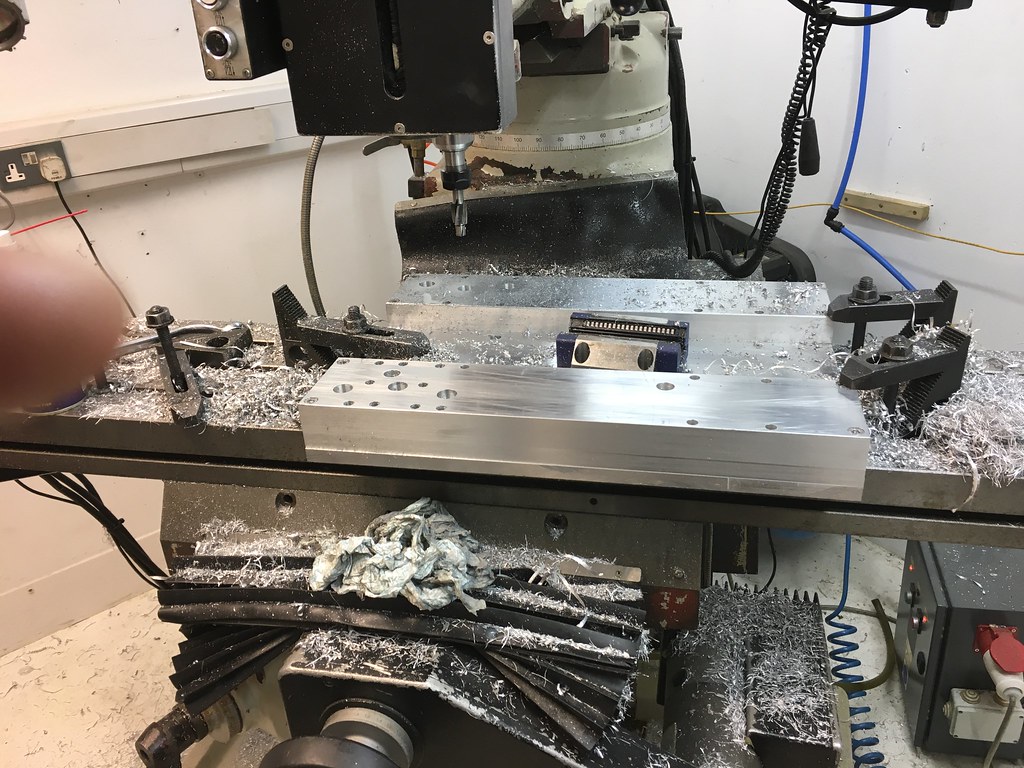

Managed to get access to a bridgeport type machine to do work on the Z Axis. Almost done, need to do a fair bit of tapping and will then assemble.

-

The Following 2 Users Say Thank You to Chaz For This Useful Post:

-

30-05-2017 #225

Last edited by Desertboy; 30-05-2017 at 10:57 AM.

http://www.mycncuk.com/threads/10880...60cm-work-area My first CNC build WIP 120cm*80cm

If you didn't buy it from China the company you bought it from did ;)

-

The Following User Says Thank You to Desertboy For This Useful Post:

-

30-05-2017 #226

-

30-05-2017 #227http://www.mycncuk.com/threads/10880...60cm-work-area My first CNC build WIP 120cm*80cm

If you didn't buy it from China the company you bought it from did ;)

-

30-05-2017 #228

I need to check, I bought two sets of components from my supplier, I think all in for 4 x 1180mm 45 Bosch rails plus carts plus around 6 different ballscrews (longer length) and 2 shorter length ones plus the a short set of rails and the Rosa ones being used on my Z Axis (700mm) was around €2500 or 3000. Not cheap but the 'list' price on a Bosch 45 Rexroth with rollerbearings and a set of carts is around €1K per set.

-

The Following User Says Thank You to Chaz For This Useful Post:

-

30-05-2017 #229

That seems reasonable I was thinking it would be even more! Amazing how being into cnc changes your perspective of reasonable lol.

So glad I only want to do aluminium and wood. This is definitely the most interesting (Read loony toons) cnc build I've ever seen if only for it's grandeur.http://www.mycncuk.com/threads/10880...60cm-work-area My first CNC build WIP 120cm*80cm

If you didn't buy it from China the company you bought it from did ;)

-

30-05-2017 #230

-

The Following User Says Thank You to Chaz For This Useful Post:

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Reply With Quote

Reply With Quote

Bookmarks